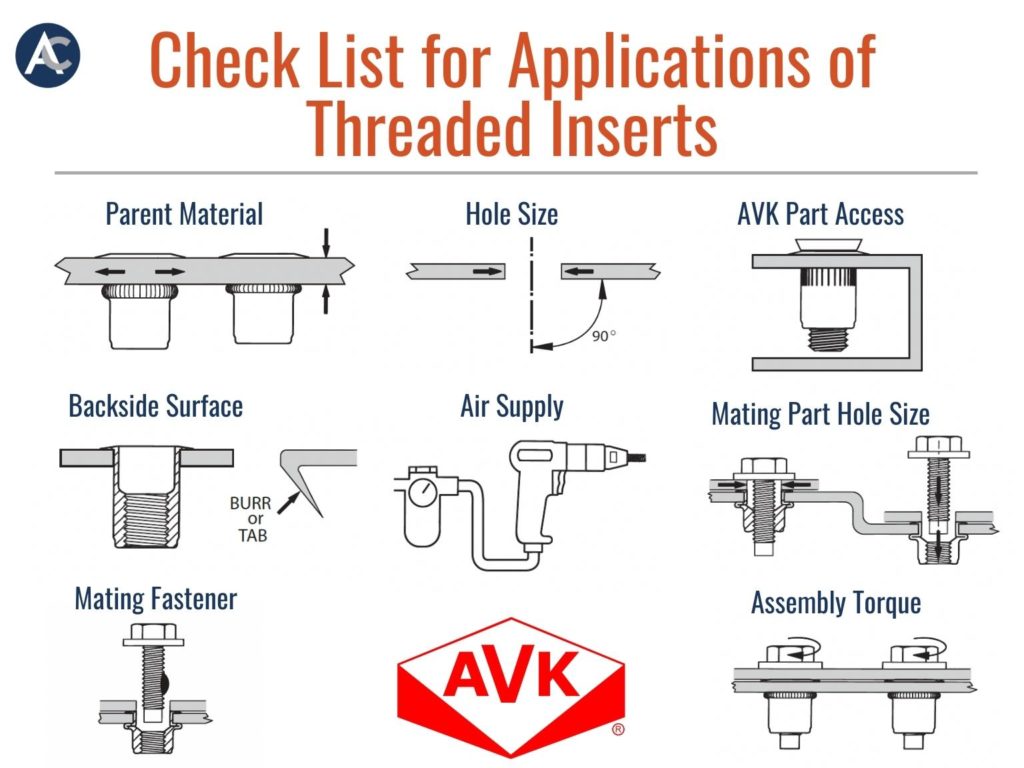

Proper application of blind threaded inserts is important for the strength of the connection. This checklist will ensure that you have considered all of the factors before proceeding with the application. From the materials used to how the fastener should sit, this list provided by AVK Industrial Products covers everything you need for a successful installation.

Parent Material

The parent material should be dense enough to support the hole fill and clamp load applied by the fastener during installation. Its thickness should be within the grip range of the fastener. Experimentation is suggested to determine optimum fastener selection for plastics.

Hold Size

The hole produced in the parent material should be per the product catalog specifications. Tolerance for paint or coating buildup should be included to avoid an undersized hole condition. The hole should be square to the parent material.

Part Access

The fastener head should sit flat on the parent material. An obstruction to the tail of the fasteners or to the access of the power tool can be corrected by contacting Advance for alternative fastener designs and tooling configurations. The installation tool should be held perpendicular to the application to void excess mandrel wear.

Backside Surface

The backside surface of the parent material should not contain a punch slug or excessive burr that exceeds the grip range of the fastener. Such large obstructions may prohibit the fasteners from installing properly.

Air Supply

AVK’s Spinwall Technology ARO brand installation tools require a pressure range of 60-110PSI (4,1-7,5 BARS) at 25 S.C.F.M. of volume. Hose and fitting inside diameters need to be a minimum of 5/16 (7,92). An inline oiler and pressure regulator is required. Pressure should be measured as dynamic with the tool running.

Mating Part Hole Size/Alignment

The mating part being attached should be non-rotational and contact the head of the fastener. Its hole size should be .040 (1,0) smaller than the head diameter of the fastener. The alignment of the mating part must provide perpendicular entry of the mating fastener into the fastener.

Mating Fastener

For AVK’s A-L, A-K, A-T, A-W and A-O Series inserts, the mating fastener should be of a “free-spinning” design and of the grade or class as indicated in the product catalog. If a mechanical, chemical locking or prevailing torque element is required, AVK recommends the design selection of the A-H Series in a mex punched hole. Specification of a dog point screw will minimize cross threading and speed the assembly process in any AVK application. Mating screws should be hand started and then power driven to minimize cross threading.

Assembly Torque

For appropriate assembly torques, see the suggested assembly torque data contained here. AVK’s products have been designed to be compatible with the torque requirements of Grade 5 or Metric Class 8.8/9.8 screws. AVK suggests customer testing to determine the optimum torque due to mating component fit and mating fastener lubrication/finish variations.

About Blind Installed Threaded Inserts

AVK blind installed threaded fasteners have internal or external threads that can be installed into a panel, tube or other structure from the front side without having to see or access the backside, or “blind” side to complete the installation. Once installed, AVK inserts remain captive so that a mating component can be attached using standard hardware.

About AVK

AVK Industrial Products is located in Southern California. AVK manufactures blind installed threaded fasteners for transportation and general industrial markets throughout the world. Advance Components has been a master stocking distributor of AVK inserts and installation tools for 37 years. The Advance Team is highly trained in AVK applications and tool repair.