Working with fluid systems requires precision, reliability, and the right tools. Whether you’re a professional mechanic, HVAC technician, or industrial maintenance worker, hose clamp pliers are essential for installing, removing, and adjusting hose clamps quickly and safely.

In this comprehensive guide, we’ll explore everything you need to know about hose clamp pliers, how to use them effectively, and why Caillau products from Advance Components are the professional’s choice for demanding applications.

What Are Hose Clamp Pliers?

Hose clamp pliers are specialized tools engineered to grip and manipulate clamps used on hoses, tubing, and fluid lines. Unlike standard pliers, these tools feature specially designed jaws that securely engage various clamp profiles without damaging the clamp, hose, or fitting.

Whether you’re working with fuel lines, coolant hoses, air connections, or hydraulic systems, hose clamp pliers provide the precise leverage needed to open and close clamps efficiently—ensuring leak-free, secure connections every time.

Types of Clamps Compatible with Hose Clamp Pliers

Professional hose clamp pliers work with multiple clamp styles:

- Spring clamps – Constant-tension clamps that maintain pressure across temperature changes

- Ear clamps – Single-use clamps compressed with specialized pliers

- Clic and Clic-R clamps – Premium constant-tension clamps from Caillau

- Spring-band clamps – Reusable clamps ideal for automotive applications

Why Hose Clamp Pliers Are Essential

1. Prevent Damage to Components

Standard pliers or screwdrivers can scratch, bend, or break clamps and damage expensive hoses. Hose clamp pliers feature non-marring jaws designed specifically for safe clamp manipulation.

2. Save Time and Effort

The ergonomic design and mechanical advantage of quality hose clamp pliers make installation and removal faster—especially in tight spaces where access is limited.

3. Ensure Proper Installation

Correctly installed clamps create uniform sealing pressure around the entire hose circumference, preventing leaks and extending component life.

4. Reduce Hand Fatigue

Professional-grade pliers like those from Caillau feature ergonomic handles that reduce strain during repetitive use—critical for technicians working on multiple vehicles or systems daily.

Caillau: The Industry Standard for Hose Clamp Solutions

Caillau has been setting the standard in engineered clamping solutions for decades. As a leading global manufacturer, Caillau products are trusted by OEMs and maintenance professionals worldwide for their precision engineering, durability, and consistent performance in demanding environments.

At Advance Components, we proudly partner directly with Caillau to offer their complete line of hose clamp pliers, Clic clamps, and clamp kits—all backed by our same-day shipping.

1. Caillau Hose Clamp Pliers

Built specifically for professionals, Caillau hose clamp pliers are engineered for compatibility with Clic and Clic-R constant-tension clamps. These precision tools allow for quick, damage-free installation and removal without compromising hose integrity or fitting surfaces.

Key Features:

- Ergonomic non-slip handles for extended use

- Secure grip on constant-tension and spring-band clamps

- Non-marring hardened jaws protect clamp surfaces

- Compatible with multiple clamp diameters

- Professional-grade construction for long tool life

Ideal Applications:

- Automotive repair shops and dealerships

- HVAC installation and service

- Marine engine maintenance

- OEM assembly lines

- Industrial equipment repair

🔗 Shop Caillau Hose Clamp Pliers →

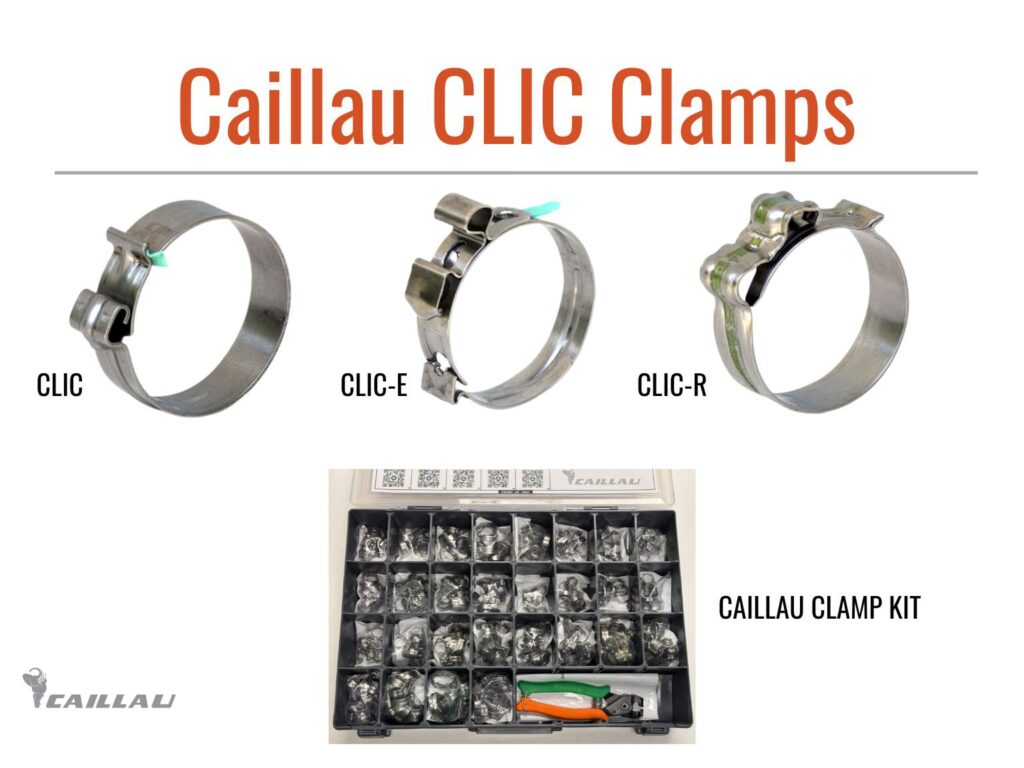

2. Caillau Hose Clamps (CLIC, CLIC-E & CLIC-R Series)

Caillau’s ClIC, CLIC-E and CLIC-R clamps represent the gold standard in constant-tension clamping technology. These premium clamps provide uniform sealing pressure that automatically adjusts to compensate for thermal expansion, vibration, and aging—critical for applications where reliability is non-negotiable.

Why Constant-Tension Clamps?

Traditional worm-drive clamps can loosen over time due to temperature cycling and vibration. Constant-tension clamps like Caillau’s CLIC series maintain consistent pressure throughout the component’s service life, reducing warranty claims and preventing costly failures.

Applications:

- Automotive cooling systems

- Fuel and emission systems

- Air intake and turbocharger connections

- Power steering and brake lines

- Industrial fluid handling systems

🔗 Explore Caillau Hose Clamps →

3. Caillau Clamp Kit – Complete Solution for Professionals

The Caillau Clamp Kit is the ultimate solution for service departments, field technicians, and maintenance teams who need versatile clamping solutions ready at hand.

What’s Included:

- Assortment of CLIC and CLIC-R clamps in multiple sizes

- Professional-grade Caillau hose clamp pliers

- Organized storage case for easy transport

- Size reference guide for quick selection

This comprehensive kit eliminates guesswork and ensures you have the right clamp and tool for virtually any hose assembly or repair job.

Perfect For:

- Mobile repair services

- Fleet maintenance operations

- Equipment service departments

- Industrial maintenance teams

- Marine service centers

How to Use Hose Clamp Pliers: Step-by-Step Guide

Installing a Hose Clamp with Pliers

Step 1: Select the Correct Clamp Choose a clamp sized appropriately for your hose diameter. The clamp should fit snugly but not overly compress the hose material.

Step 2: Position the Pliers Open the hose clamp pliers and position the jaws over the clamp’s ears or engagement tabs. Ensure the jaws are fully seated.

Step 3: Open the Clamp Gently squeeze the plier handles to compress the clamp and open it to its expanded diameter.

Step 4: Slide into Position While holding the clamp open, slide it over the hose and onto the fitting. Position the clamp beyond the bead or ridge on the fitting.

Step 5: Release and Verify Slowly release the plier handles, allowing the clamp to contract evenly around the hose. Verify the clamp is positioned correctly and has uniform compression.

Removing a Hose Clamp

Step 1: Access the Clamp Position your hose clamp pliers to access the clamp tabs or ears. You may need angled or straight-jaw pliers depending on workspace constraints.

Step 2: Compress the Clamp Squeeze the plier handles to compress the clamp and release its tension on the hose.

Step 3: Slide Off Carefully While maintaining pressure on the pliers, carefully slide the clamp away from the fitting and off the hose.

Step 4: Inspect Components Check both the hose and fitting for wear, damage, or contamination before reinstalling or replacing the clamp.

Pro Tip: When working in confined spaces, consider using hose clamp pliers with angled jaws or flexible cables that allow access where standard tools won’t reach.

Applications Across Industries

Automotive Applications

Hose clamp pliers are indispensable in automotive repair and maintenance:

- Cooling systems – Radiator hoses, heater core connections

- Fuel systems – Fuel lines, vapor recovery systems

- Air intake – Turbocharger connections, intercooler hoses

- Emissions – EGR systems, PCV connections

- Power steering – High-pressure and return lines

Modern vehicles use constant-tension clamps extensively because they maintain seal integrity despite underhood temperature extremes and vibration.

HVAC Applications

HVAC technicians rely on quality hose clamp pliers for:

- Air handler condensate lines

- Refrigerant line connections

- Coolant circulation systems

- Ductwork flexible connections

- Condensate pump tubing

Marine Applications

The marine environment demands corrosion-resistant clamps and proper installation tools:

- Engine cooling systems

- Fuel delivery systems

- Bilge pump connections

- Sanitation systems

- Freshwater plumbing

Stainless steel Caillau clamps paired with proper installation tools ensure reliable performance in harsh saltwater environments.

Industrial Applications

Manufacturing and industrial facilities use hose clamp pliers for:

- Compressed air distribution

- Hydraulic power systems

- Coolant delivery systems

- Chemical transfer lines

- Pneumatic tool connections

🔗 Explore our complete Fasteners collection →

Choosing the Right Hose Clamp Pliers

When selecting hose clamp pliers for your application, consider:

Jaw Design

- Straight jaws – Best for open, accessible areas

- Angled jaws – Ideal for reaching into confined spaces

- Flexible cable – Necessary for extremely tight locations

Handle Ergonomics

Look for cushioned, non-slip grips that reduce hand fatigue during extended use. Professional-grade tools like Caillau pliers feature ergonomically designed handles that distribute pressure evenly.

Build Quality

Professional tools should feature:

- Heat-treated steel construction

- Corrosion-resistant finishes

- Precise jaw alignment

- Smooth operation without binding

- Durable pivot mechanisms

Clamp Compatibility

Ensure your pliers are designed for the specific clamp types you work with most frequently. Caillau hose clamp pliers are engineered specifically for their Clic and Clic-R clamp systems, ensuring optimal performance.

Maintenance Tips for Hose Clamp Pliers

Extend the life of your hose clamp pliers with proper care:

- Clean Regularly – Remove dirt, oil, and debris after each use

- Lubricate Pivot Points – Apply light machine oil to maintain smooth operation

- Inspect Jaws – Check for wear, damage, or misalignment

- Store Properly – Keep in a clean, dry environment; avoid throwing tools in toolboxes

- Check Spring Tension – Ensure return springs maintain proper jaw opening

Common Mistakes to Avoid

Using the Wrong Tool

Standard pliers, vise-grips, or screwdrivers can damage clamps and hoses. Always use proper hose clamp pliers designed for the clamp type.

Over-Compressing Clamps

Excessive force can permanently deform spring clamps, reducing their sealing effectiveness. Use only enough pressure to open the clamp.

Incorrect Clamp Positioning

Clamps must be positioned beyond the fitting’s sealing bead. Improper placement leads to leaks regardless of clamp quality.

Reusing Single-Use Clamps

Ear clamps and crimp-style clamps are designed for one-time use. Always replace these with new clamps during reassembly.

Mixing Incompatible Components

Use clamps and pliers from the same manufacturer system (like Caillau’s Clic clamps with Caillau pliers) for optimal performance.

Get Started with Professional Caillau Solutions Today

Don’t compromise on quality when it comes to critical fluid system connections. Invest in authentic Caillau hose clamp pliers, clamps, and kits from Advance Components—backed by decades of engineering excellence and our commitment to same-day shipping and superior customer service.

Whether you’re outfitting a professional shop, maintaining a fleet, or need reliable tools for field service, we have the Caillau solutions you need.

Have questions about which Caillau products are right for your application? Contact our expert team – we’re here to help you find the perfect solution.