Rivet nuts, inserts, rivnuts – are the perfect auto shop fasteners. When it comes to repairing and manufacturing custom cars, trucks and trailers – rivet nuts, tools, pliers and rivet drivers are used extensively for joining sheet metal components and attaching accessories and hardware. Having the right combination of rivet insert nuts and tools is essential for an auto shop to run smoothly. When a shop has a Rivet Nut kit on hand, technicians are more efficient as the inserts are on hand and ready to use.

What is a Rivet Nut – Rivnut – Blind Threaded Insert – Nut-sert?

Rivet nuts are blind installed threaded fasteners that have internal or external threads that can be installed into a panel, tube or other structure from the front side without the need to see or access the backside, or the “blind” side to complete installation. Once the insert or rivnut is installed, it remains captive to which a mating component can be attached using standard hardware.

How is a Rivet Nut used in the body shop?

Auto repair shops need rivet nut insert kits for a few key reasons:

-

Body panel repairs and replacements

Many auto body panels are attached using rivet nuts or nut-serts. When replacing panels like fenders, doors, trunk lids etc, the old rivet nuts often need to be removed and new ones installed in the replacement panel.

-

Attaching accessories and components

Rivet nuts provide a durable threaded hole in thin metal sheets. Repair shops use them to attach things like towing hitches, roof racks, auxiliary lights and other accessories to the vehicle body where there are no pre-existing threaded holes.

-

Repairing stripped threads

If a threaded hole in a bracket, frame member etc gets stripped or damaged, a rivet nut insert can be used to restore and reinforce the threaded hole.

-

Faster installation

Compared to welding nuts or tapping threads, installing rivet nuts using the supplied tools in the kit is generally faster and easier for auto technicians.

Why Use Rivet Nut Kits?

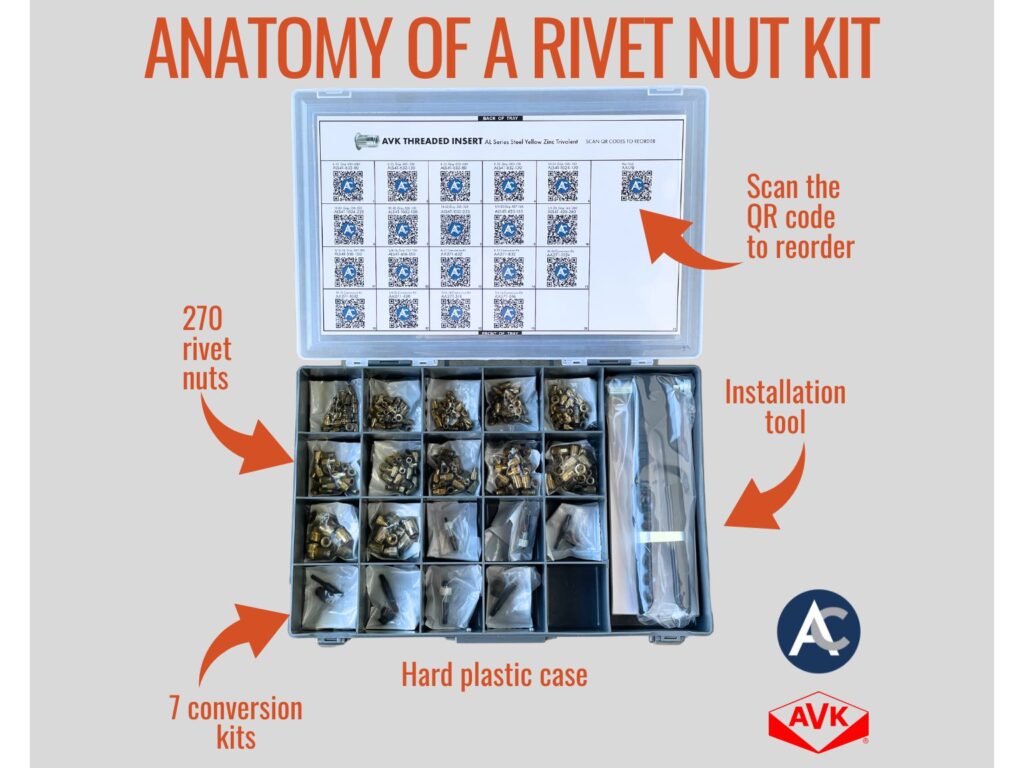

Running a tight and efficient repair shop is paramount for success in such a competitive market, and keeping fasteners contained and organized can sometimes be challenging. Having contained kits of rivet nuts in various sizes gives the technician an easily accessible choice when completing repairs. Kits have a scannable QR code for each size and style of rivet nut and installation tool for easy reordering.

What’s in a Rivet Nut Kit?

There are many types of rivet kits that feature an assortment of rivet sizes and installation tools. Here are Advance Components, we build rivnut kits that contain AVK inserts. Each hard plastic kit contains 270 rivet nuts, 7 conversion kits and one installation tool, either a plier tool or a HI Torquer tool.

AVK is the leading USA based manufacturer of rivet nuts used in a variety of truck, car and trailer applications including:

- Mirrors/light to cab

- Grab handles to cab

- Firewall attachments

- Instruments to dash

- Exhaust/wind deflectors

- Luggage racks to roof

- Spoilers to truck lids

Benefits to Using AVK Rivet Nuts in an Auto Repair Shop

AVK is the leading domestic manufacturer of rivet nuts in the industry. Strong USA-made inserts make for a strong and secure connection that you can trust.

-

Joining sheet metal components

AVK rivet nuts allow for easily joining and securing thin sheet metal panels, brackets, and other components together. This is useful for the body, frame rails, running boards, and other sheet metal assemblies on trucks and trailers.

-

Attaching accessories and hardware

AVK rivet nuts provide threaded holes in the sheet metal to attach things like lights, mud flaps, steps, hitches, tool boxes and other accessories securely without welding.

-

Facilitating assembly and disassembly

Using AVK rivet nuts instead of welding allows components to be assembled, disassembled and replaced more easily during manufacturing and repairs.

-

Vibration resistance

AVK rivet nuts, when properly installed, are highly resistant to loosening from vibrations that trucks and trailers experience on the road.

-

Access limitations

In some confined spaces or areas with limited access during assembly, installing AVK rivet nuts is easier than trying to weld nuts or tap threads directly.

-

Cost and time savings

Compared to welding nuts or threading holes, installing AVK rivet nuts can be a quicker and more cost-effective joining method for high-volume production.

The durability, ease of installation/removal and versatility of AVK rivet nuts make them well-suited for the simple or complex repairs on automobiles, trucks and trailers.

AVK Rivet Nut Kits at Advance

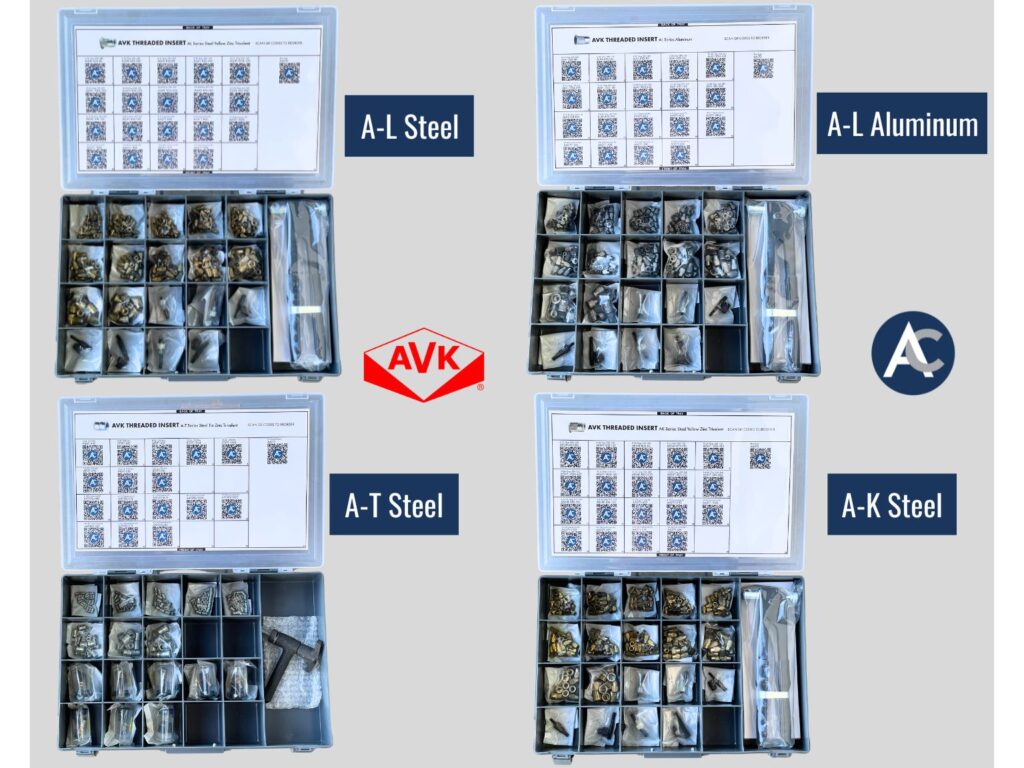

AVK Rivet Nut Kits for inserts A-T steel, A-L steel, A-L aluminum, and A-K steel are available at advancecomponents.com. Same shipping is available for all kits purchased before 2PM from our Dallas-based warehouse. Advance also stocks a large assortment of AVK rivets, installation tools and components.