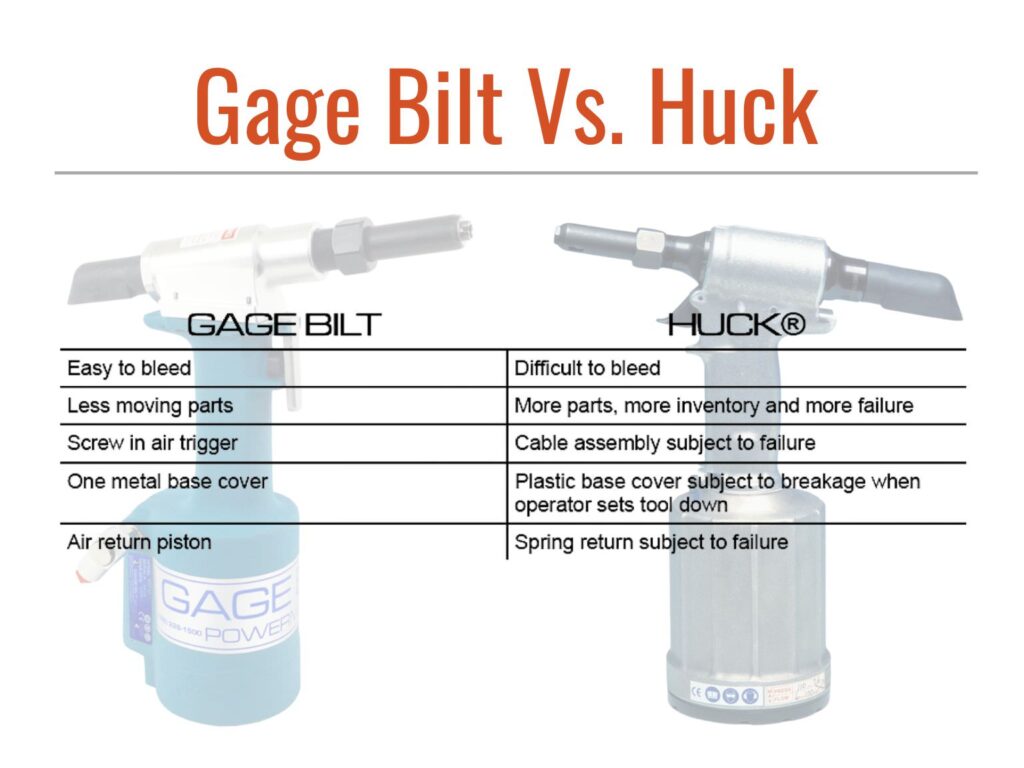

In the high-stakes world of industrial fastening, choosing the right rivet tool is paramount. Two leading contenders emerge: Gage Bilt and Huck. Both offer robust, reliable tools for tackling demanding jobs, but each has its own strengths and weaknesses. Let’s delve into the specifics of Gage Bilt Vs. Huck Rivet Tools to help you decide which brand reigns supreme for your needs.

Tool Selection and Capabilities:

-

Gage Bilt: Boasts a wider variety of tools, catering to diverse applications. Their manual, pneumatic, and hydraulic rivet tools handle an extensive range of rivet types and sizes, including blind rivets, lockbolts, and structural rivets.

-

Huck: Primarily focuses on high-strength Huck-branded rivets and lockbolts, offering exceptional performance in demanding applications like aircraft construction and bridgework. Their tool selection caters specifically to their fastener range.

Ergonomics and User Experience:

-

Gage Bilt: Generally known for their lightweight, ergonomic designs, minimizing operator fatigue during extended use. Many models feature comfortable grips, balanced weight distribution, and low vibration levels. This advantage is crucial for repair technicians who spend long hours working on vehicles.

-

Ease of use: Gage Bilt tools are generally user-friendly, requiring less training and setup compared to some heavier-duty options. This is beneficial for smaller repair shops or individuals who need tools that are readily accessible and operable without extensive expertise.

-

Huck: Tools tend to be heavier and more robust, prioritizing sheer power and durability over comfort. While not as user-friendly for extended periods, they excel in heavy-duty applications where raw strength is crucial.

Versatility:

-

Wider range of tools: Gage Bilt offers a broader selection of tools, including manual, pneumatic, and hydraulic options, suitable for various tasks and rivet types. This flexibility is ideal for truck and trailer repair which often involves diverse materials and fastening needs.

-

Handles different rivet types: Unlike Huck’s focus on their specific rivets, Gage Bilt tools can handle a broader range of standard blind rivets, lockbolts, and even structural rivets commonly used in truck and trailer construction and repair.

-

Tool kits: Gage Bilt offers specialized tool kits designed specifically for truck and trailer repair. These kits include commonly used tools and accessories, saving time and money compared to purchasing individual items.

-

Additional features: Some Gage Bilt tools offer features like low noise levels, adjustable trigger mechanisms, and enhanced safety features, which can be important considerations for repair technicians working in confined spaces or with safety regulations.

Price and Availability:

-

Price: Gage Bilt tools are often more affordable than Huck, making them a more cost-effective option for budget-conscious repair shops or individuals. This factor can be significant when maintaining large fleets of trucks and trailers.

-

Availability: Spare parts and accessories for Gage Bilt tools are generally more readily available, minimizing downtime and ensuring easy maintenance. This is crucial in the fast-paced world of truck and trailer repair where delays can be costly. Gage Bilt rivet tools are available at Advance.

-

Huck: Known for their premium pricing, reflecting the focus on high-performance tools and specialized fasteners. Parts and accessories might have limited availability outside specific industries.

The Verdict:

Gage Bilt Vs. Huck Rivet Tools: Choosing between Gage Bilt and Huck hinges on your specific needs and priorities. If you require a versatile tool for various fastening tasks and prioritize value, Gage Bilt might be the ideal fit. On the other hand, if your focus is on high-strength applications where ultimate performance and durability are non-negotiable, Huck could be the better option.

Of course, the choice between Gage Bilt and Huck ultimately depends on individual needs and priorities. While Huck might be preferable for specific high-strength applications, Gage Bilt’s overall versatility, user-friendliness, cost-effectiveness, and specific features make it a compelling option for many truck and trailer repair shops and technicians.