In the world of industrial fasteners, weld nuts represent a critical component for numerous manufacturing applications.

Weld Nuts are specialized fastening solutions that offer permanent, strong connections across various industries including automotive, farm equipment, construction, and general manufacturing.

This guide will explore the unique benefits of several types of weld nuts manufactured by Buckeye Fasteners Company that are available at Advance Components. You’ll discover their unique benefits, and how to select the right weld nut for your specific application needs.

What Are Weld Nuts?

Weld nuts are threaded fasteners designed to be permanently attached to metal surfaces through welding processes. Unlike standard nuts that require access to both sides of an assembly, weld nuts create threaded attachment points on one side of a surface, eliminating the need for through-holes in many applications.

The advantages of using weld nuts include:

- Creating permanent, secure threaded connections

- Reducing assembly time and labor costs

- Eliminating the need for access to both sides of an assembly

- Providing consistent, repeatable thread locations

- Enhancing the structural integrity of the final assembly

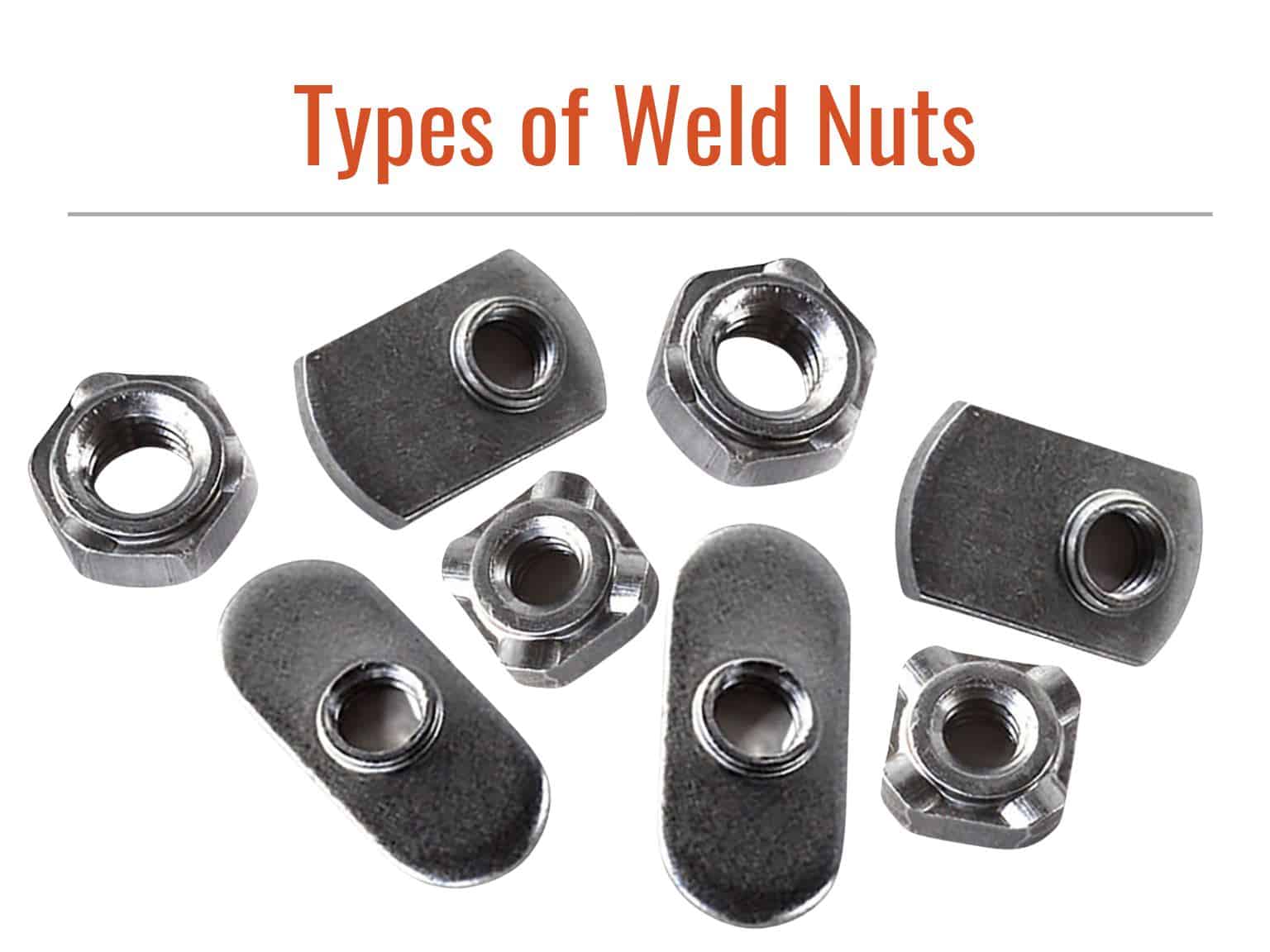

Types of Weld Nuts

Advance Components stocks premium quality weld nuts manufactured by Buckeye Fasteners, a trusted industry leader. Let’s explore the four primary styles of weld nuts in our inventory.

1. Square Piloted 4-Projection Weld Nuts (WP)

WP weld nuts feature a square piloted projection specifically designed for through-hole applications. These versatile fasteners have been longtime favorites in automotive and farm equipment manufacturing due to their exceptional reliability and strength.

Key Features:

- Precision pilot for quick and positive location in sheet holes

- Rounded corners for easy use in confined spaces

- Four large weld projections ensuring strong, dependable welds

- Countersunk locating pilot to guide mating parts into the threaded hole

- Available in various pilot heights for compatibility with different metal thicknesses

Ideal Applications:

- Automotive frame and body assembly

- Heavy equipment manufacturing

- Farm machinery production

- Applications requiring high-strength permanent connections

2. Hex Piloted 3-Projection Weld Nuts (HS)

HS weld nuts are distinguished by their three uniform projections that ensure reliable contact with weld surfaces, even when working with imperfectly flat materials.

Key Features:

- Three evenly spaced projections for consistent weld contact

- Precision pilot that accurately locates threads in pilot holes

- Design that prevents off-center slippage during welding

- Reliable performance on uneven surfaces

Ideal Applications:

- Sheet metal fabrication

- General manufacturing

- Applications with potential surface irregularities

- Projects requiring precise thread alignment

3. Single-Tab Spot Weld Nuts (SN)

The SN weld nut, also known as an economy t-nut, features a precision pilot and optimum welding tab design that accommodates various electrode sizes.

Key Features:

- Compatible with existing welding equipment and settings

- Can function as both a fastener and structural stiffener/brace

- Optimized tab design for versatile electrode compatibility

- Cost-effective fastening solution

Ideal Applications:

- Production environments using standardized welding equipment

- Applications requiring additional structural support

- Projects with budget constraints

- Manufacturing processes where minimizing setup changes is valuable

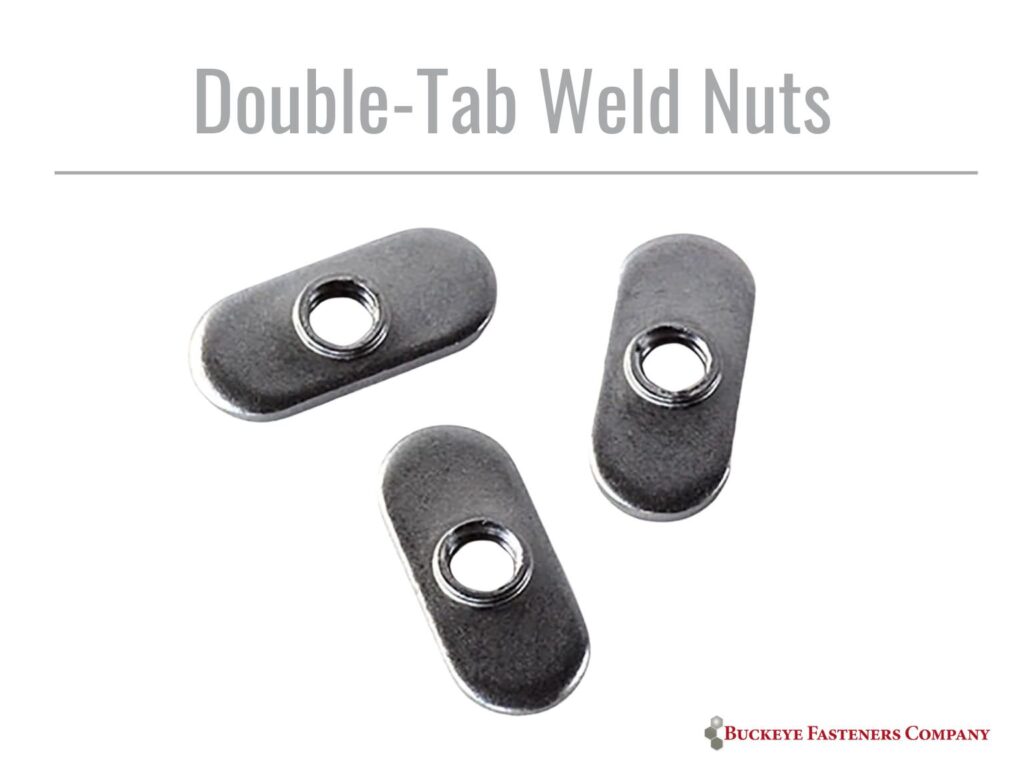

4. Double-Tab Spot Weld Nuts (ND)

ND weld nuts feature dual welding tabs for applications demanding additional strength, particularly where tension is against the weld. These are the standard slot fasteners in the aluminum extrusion industry.

Key Features:

- Twin tabs for bridging corners and recessed areas

- Precision pilot for fast location and full thread engagement

- Compatible with standard production electrodes and equipment

- Eliminates setup and changeover time, reducing costs

Ideal Applications:

- Aluminum extrusion industry

- Corner and recessed area connections

- High-tension applications

- Manufacturing processes requiring cost efficiency

Selecting the Right Weld Nut

Choosing the appropriate weld nut depends on several factors related to your specific application:

Material Thickness Considerations

The thickness of the base material is a critical factor in weld nut selection. Various pilot heights are available for different material thicknesses:

- Thin materials (under 1/16″): Consider SN or ND weld nuts

- Medium thickness (1/16″ to 1/8″): WP or HS weld nuts work well

- Thicker materials: Select WP weld nuts with appropriate pilot heights

Welding Process Compatibility

Different weld nut styles are optimized for specific welding processes:

- Projection welding: WP and HS styles excel here

- Spot welding: SN and ND designs are specifically engineered for this process

- Resistance welding: All four styles are compatible, but with varying optimal parameters

Load Requirements

The anticipated load on the connection should guide your weld nut selection:

- High tensile loads: WP weld nuts with four projections offer maximum strength

- Shear loads: HS weld nuts provide excellent performance

- Combined loads: Consider WP or ND depending on the specific force distribution

Space Constraints

The available space in your assembly may dictate your weld nut choice:

- Confined spaces: WP weld nuts with rounded corners facilitate installation

- Recessed areas: ND weld nuts with dual tabs are ideal

- Standard open areas: Any style can work effectively

Installation Best Practices

To achieve optimal performance from your weld nuts, follow these installation guidelines:

- Surface Preparation: Ensure welding surfaces are clean and free from contaminants

- Alignment: Properly align weld nuts using their pilots before welding

- Equipment Settings: Follow manufacturer recommendations for welding parameters

- Inspection: Verify weld quality before proceeding with assembly

- Thread Protection: Consider using thread protectors during painting or coating processes

Related Weld Fastener Solutions

While exploring weld nut options, you might also be interested in other related fastening solutions manufactured by Buckeye Fasteners that are available at Advance.

- Weld Screws – Alternative fasteners for certain welded assemblies

- Projection Weld Pins – Complementary fasteners for specific applications

Finding Your Ideal Weld Nut Solution

Selecting the right weld nut is essential for ensuring the structural integrity, efficiency, and longevity of your manufacturing projects. Advance Components offers a comprehensive selection of high-quality Buckeye Fasteners weld nuts to meet your specific application requirements.

Contact Advance Components today to discuss your weld nut requirements and discover how our premium fastening solutions can enhance your manufacturing processes. Whether you’re working on automotive assemblies, farm equipment, or general manufacturing applications, we have the expertise and inventory to support your fastening needs.