In the world of professional fastening solutions, cage nuts stand as one of the most versatile and reliable options for securing components to panels with square holes. Whether you’re building server racks, assembling HVAC equipment, or constructing automotive components, cage nuts provide the perfect combination of strength, convenience, and reliability that modern industries demand.

For a detailed technical explanation of cage nut mechanics, check out our comprehensive resource: How Do Cage Nuts Work?

The Ultimate Panel Fastening Solution

Cage nuts, also known as rack and captive nuts, represent an innovative approach to fastening that combines the functionality of a spring steel fastener with a high-strength multi-threaded nut. These self-retaining fasteners are specifically engineered for rack and equipment mounting applications where traditional nuts would be impractical or impossible to use effectively.

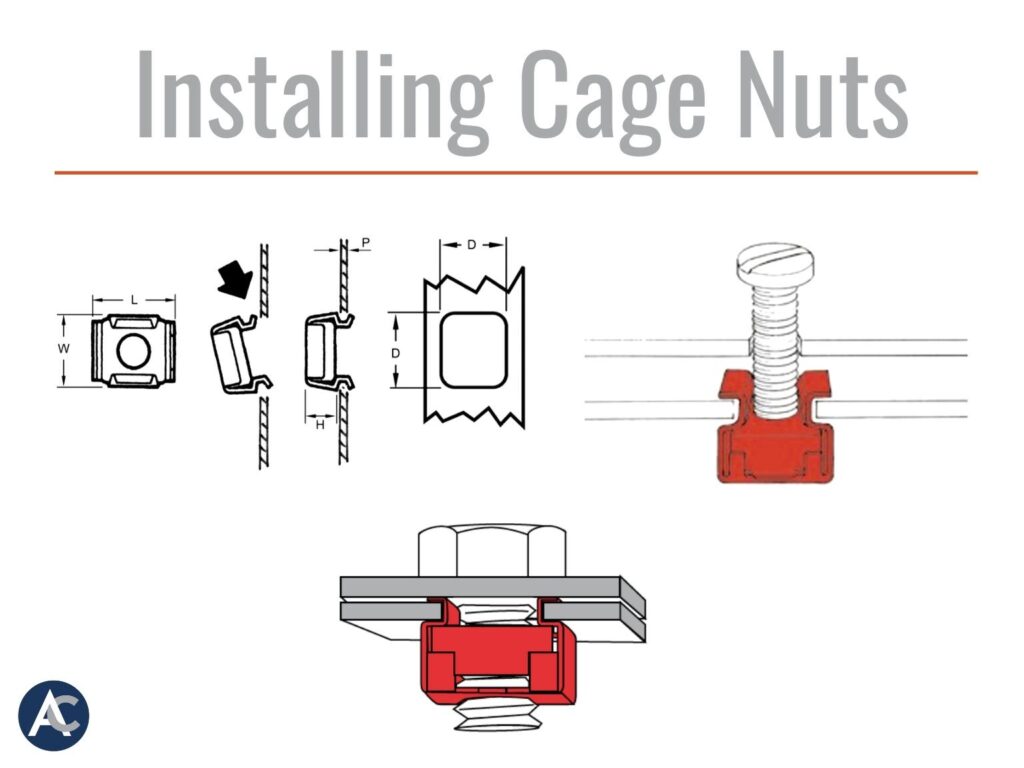

The genius of cage nut design lies in their spring-steel “mechanical hands” or wings that maintain the nut’s stationary position within square holes. This unique design eliminates the frustration of dropped nuts, misaligned threads, and the need for access to both sides of the panel during installation.

Why Cage Nuts Excel Over Traditional Fastening Methods

Superior Installation Convenience

Cage nuts require no special tools for installation, making them incredibly user-friendly for professionals across industries. The snap-in design allows technicians to position fasteners quickly and securely, even in challenging or cramped working conditions.

Exceptional Blind Location Assembly

For applications where panel access is limited to one side, cage nuts provide an unmatched solution. Their self-positioning design ensures proper alignment and secure attachment without requiring rear panel access, making them ideal for dense equipment installations.

Outstanding Pullout Resistance

The spring-loaded retention mechanism of cage nuts provides excellent resistance to pullout forces. Once installed, these fasteners maintain their position under vibration, thermal cycling, and mechanical stress, ensuring long-term reliability in demanding applications.

Anti-Rotation Design

Unlike traditional nuts that can spin during bolt tightening, cage nuts remain stationary thanks to their spring-steel wings. This feature dramatically reduces installation time and prevents the frustration of loose or improperly secured connections.

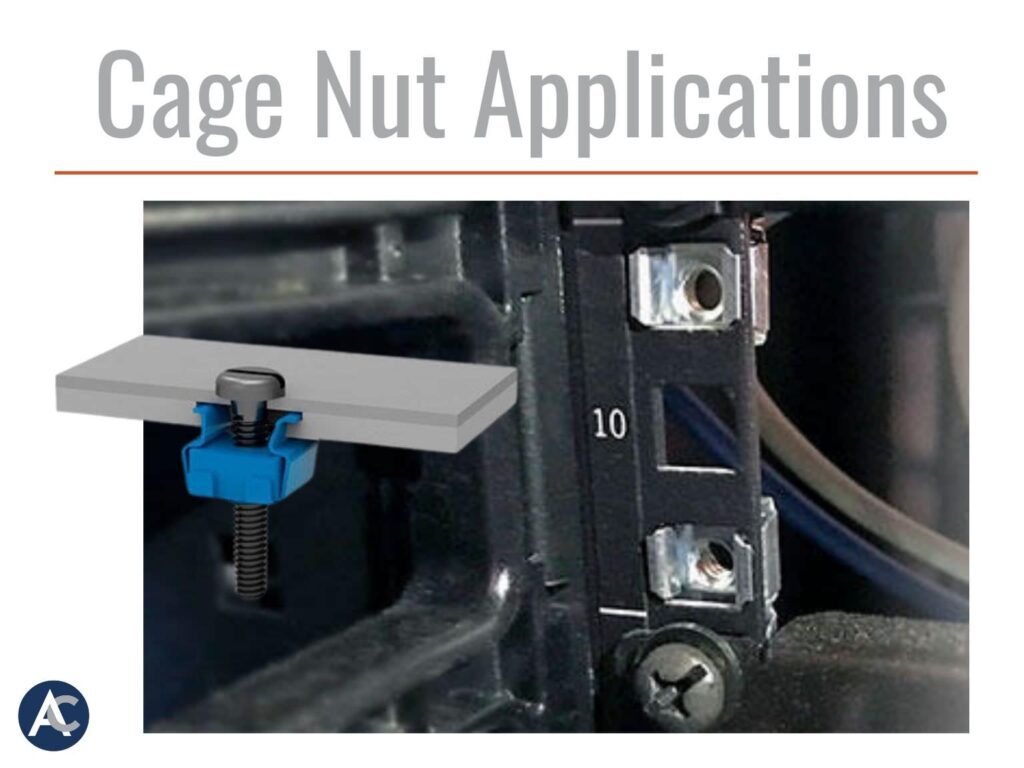

Applications for Cage Nuts

Server Rack Construction and Data Centers

In modern data centers, cage nuts are essential for mounting servers, switches, and networking equipment. Their ability to provide secure mounting points in standard 19-inch racks makes them indispensable for IT professionals who need reliable, serviceable connections that can be modified or relocated as needed.

Cabinet and Enclosure Manufacturing

Cabinet manufacturers rely on cage nuts for creating versatile mounting systems that accommodate various component configurations. The ability to pre-install cage nuts along assembly lines provides flexibility for end-users while maintaining manufacturing efficiency.

HVAC System Assembly

Heating, ventilation, and air conditioning systems often require secure panel-to-component connections in locations where traditional fastening methods are impractical. Cage nuts provide the strength and reliability needed for HVAC applications while allowing for easy service and maintenance access.

Automotive Component Mounting

The automotive industry utilizes cage nuts for securing various components to chassis panels and structural elements. Their vibration resistance and high torque capacity make them ideal for automotive applications where reliability is paramount.

Electrical Equipment and Control Panels

Electrical equipment manufacturers use cage nuts extensively for mounting components within control panels and electrical enclosures. The secure, vibration-proof connection ensures electrical components remain properly positioned throughout their operational life.

Grill Panel and Ventilation Systems

Industrial and commercial ventilation systems often incorporate grill panels that must be securely mounted yet easily removable for maintenance. Cage nuts provide the perfect balance of security and serviceability for these applications.

Professional Grade Cage Nut Solutions

AdvanceBasics Cage Nuts

Our AdvanceBasics line of cage nuts offers exceptional value without compromising quality. These fasteners are engineered to meet rigorous industry standards while providing cost-effective solutions for high-volume applications. AdvanceBasics cage nuts feature:

- Precision-manufactured spring steel construction for consistent performance

- Optimized thread engagement for maximum holding power

- Corrosion-resistant finishes for extended service life

- Standardized sizing for compatibility with industry-standard panels

Explore AdvanceBasics Products

Installation Best Practices and Technical Considerations

Proper Installation Technique

Installing cage nuts correctly ensures optimal performance and longevity. The installation process involves positioning the cage nut at the desired square hole location and pressing firmly until the mounting legs expand around the panel. The retainer spring tabs will snap back to lock the fastener securely in place.

Panel Thickness Compatibility

Different cage nut designs accommodate various panel thicknesses. Selecting the appropriate cage nut for your specific panel thickness ensures proper retention force and optimal fastening performance.

Thread Engagement Optimization

Proper bolt selection ensures adequate thread engagement without bottoming out in the cage nut. This optimization provides maximum holding strength while allowing for easy disassembly when service is required.

Quality Assurance and Performance Standards

Professional-grade cage nuts undergo rigorous testing to ensure they meet industry standards for strength, durability, and performance. This testing includes:

- Tensile strength verification to ensure adequate holding power

- Vibration resistance testing for automotive and industrial applications

- Corrosion resistance evaluation for long-term reliability

- Installation force consistency testing for manufacturing efficiency

Cost-Effectiveness and Long-Term Value

Cage nuts provide exceptional return on investment through several key factors:

Reduced Installation Time: The no-tool installation process significantly reduces labor costs during assembly and service operations.

Enhanced Serviceability: Components can be easily removed and reinstalled without replacing fasteners, reducing maintenance costs over the equipment lifecycle.

Inventory Simplification: A single cage nut size can often accommodate multiple bolt sizes, simplifying inventory management and reducing storage costs.

Reliability Benefits: The vibration-proof, rattle-resistant design reduces warranty claims and service calls related to loose fasteners.

Selecting the Right Cage Nuts for Your Application

Size and Threading Considerations

Cage nuts are available in various sizes to accommodate standard bolt threading including #6-32, #8-32, #10-24, #10-32, 1/4-20, and metric alternatives. Selecting the appropriate thread pitch ensures optimal performance and compatibility with your existing hardware.

Material and Finish Options

Different applications require specific material properties and finish options. Standard zinc-plated steel provides excellent general-purpose performance, while stainless steel options offer superior corrosion resistance for harsh environments.

Load Requirements

Understanding the specific load requirements for your application ensures proper cage nut selection. Consider both static loads and dynamic forces that may be encountered during operation.

Maximizing Performance with Professional Cage Nuts

Professional cage nuts are manufactured to meet or exceed industry standards including automotive specifications, telecommunications requirements, and general industrial fastener standards.

Cage nuts represent a critical component in modern assembly and manufacturing operations. Whether you’re specifying fasteners for server rack construction, automotive assembly, HVAC installation, or electrical equipment manufacturing, choosing the right cage nuts ensures optimal performance and long-term value.

Our comprehensive selection of AdvanceBasics and ARaymond/Tinnerman cage nuts provides the quality and variety needed to meet any professional fastening challenge.

Shop our complete selection of cage nuts and discover the difference that quality fasteners make in your applications.