A Cage Nut is what it sounds like – a nut in a cage. It’s a multi-threaded steel nut that “floats” in a spring steel cage to offset normal holes misalignment. The “mechanical” hands on the Cage Nut hold the bolt in the receiving position so that the fastener cannot turn when the applied bolt is tightened.

Cage Nuts, also called Captive Nuts and Server Rack Nuts are ideal for applications requiring extra-high torque and holding power.

They are self-retaining and can easily be snapped into nut or bolt receiving positions by hand, anywhere along the assembly line. No welding, clinching, staking, special skills or equipment are required. Cage Nuts are rust proof, and can be applied after painting which eliminates costly masking or re-tapping paint-clogged threads.

Cage Nut Benefits

Great design – combining a high-strength multi-thread nut with spring steel fastener cage

Easy to assemble – no special tools or skills are required.

Serviceable – easy to apply and remove for fast reliable access.

Convenient – can be applied at any spot in the assembly line.

Self-retaining – holds itself in place eliminating welds, clinch fasteners.

Vibration proof – strong grip withstands movement, dislodging.

Three Popular Types of Cage Nuts

Standard Type

Standard type Cage Nuts easily snap into bolt-receiving position without the use of special equipment or skills. They provide floating alignment and eliminate weld breaks.

“J” Type

Cage Nuts that are “J” shaped snap easily over panel edges by hand, so like other styles, they don’t need special tools or skills to install. They are self-retaining in a bolt-receiving position. An extrusion in the leg of the “J” Type Cage Nut assures constant alignment.

“U” Type

U-shaped Cage Nuts are similar to J-shaped Cage Nuts but have a full lower leg. They are ideal for attachments requiring full bearing on the lower leg. The extrusion on the lower leg assures instant and constant alignment.

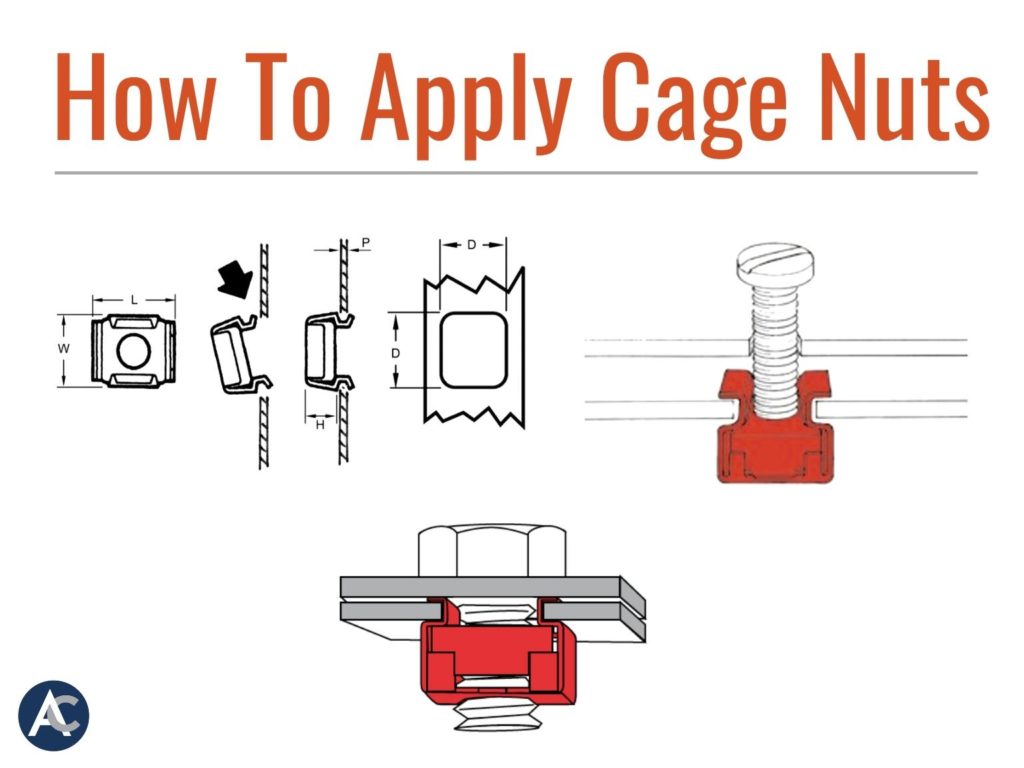

How Cage Nuts are Installed

One spring steel retaining leg of the Cage Nut is inserted into a panel hole, the other leg is snapped into place with a simple tool or by hand.

The second panel is then aligned and the bolt is started onto the threads of the nut within the Cage Nut.

When the bolt is tightened, the self-retaining Cage Nut can’t move and remains a positive, flush attachment.

Applications for Cage Nuts

Appliances

HVAC

Automotive

Lighting Equipment

Fans

Electronic Equipment

Agriculture Equipment

Furniture

Toys

In Stock & Ready To Ship

Advance Components has a large variety of Cage Nuts in stock and ready for same day shipping. Contact the Advance Sales Team for applications support, quotes and samples. Buy online 24/7 in our online store.