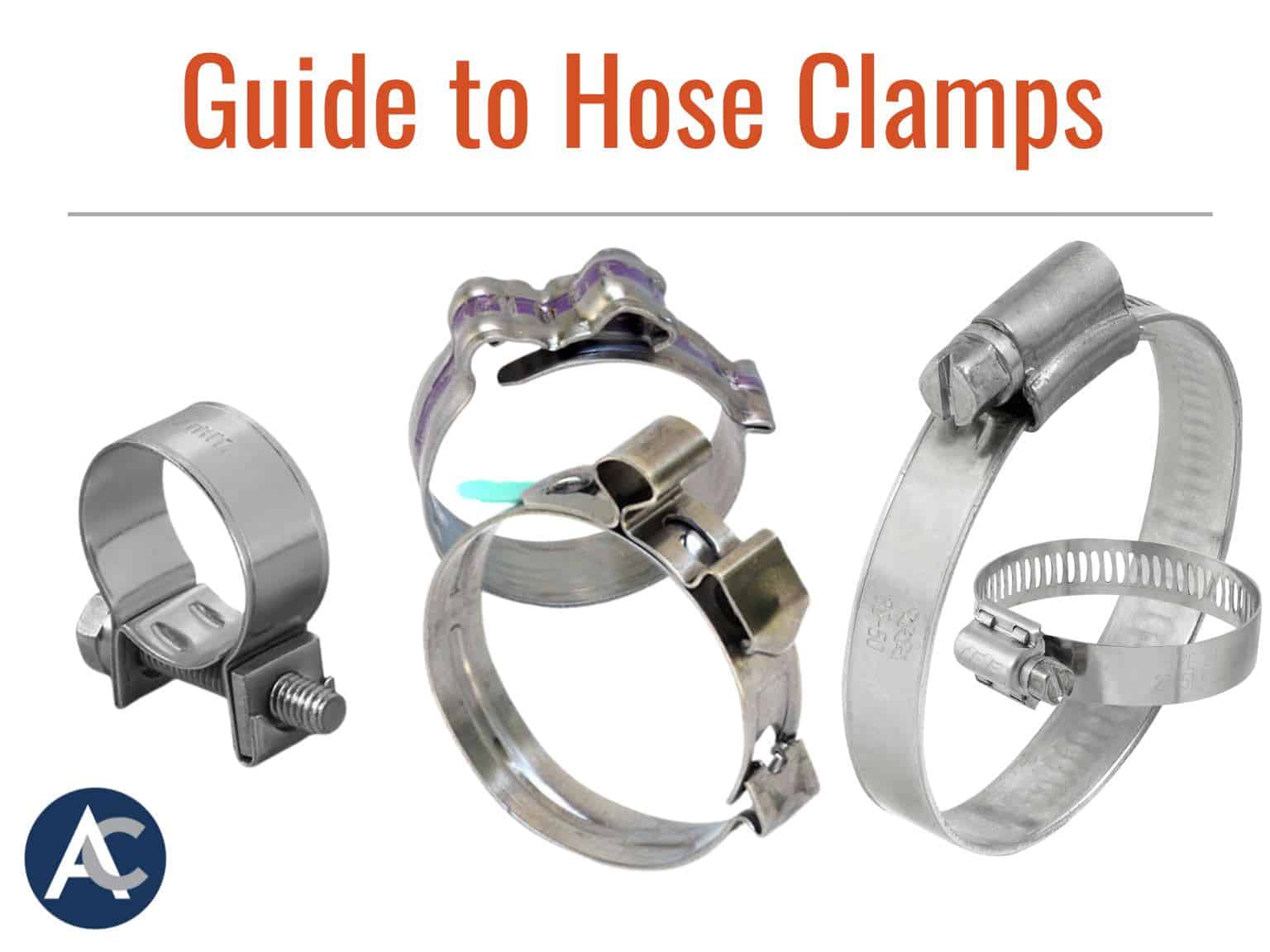

When it comes to joining hoses to fittings or connecting fluid transfer systems, few components are as essential yet overlooked as the humble hose clamp.

These deceptively simple fasteners play a critical role in countless applications, from automotive systems to industrial equipment to household plumbing.

But not all hose clamps are created equal. Understanding the different types available and their specific advantages can make the difference between a secure, leak-free connection and a costly failure.

WHAT IS A HOSE CLAMP?

At its most basic, a hose clamp is a device used to attach and seal a hose onto a fitting such as a barb or nipple. Hose clamps apply uniform pressure around the circumference of a hose, creating a tight seal that prevents leakage and disconnection. While their function might seem straightforward, the engineering behind different hose clamp designs can be quite sophisticated.

TYPES OF HOSE CLAMPS

CLIC Hose Clamps

CLIC hose clamps represent one of the most innovative developments in clamp technology. Originally developed for automotive applications where quick installation and consistent tension are crucial, these clamps have become increasingly popular across various industries.

For a deeper understanding of how these innovative fasteners compare to traditional options, read our guide on What Is a CLIC vs. Worm Gear Hose Clamp?

How They Work: Unlike traditional clamps, CLIC clamps feature a unique spring steel construction with a pre-formed shape. When compressed for installation, they create consistent, radial pressure that maintains tension even as the hose material ages or expands/contracts with temperature changes.

Key Advantages:

- Tool-free installation and removal

- Constant tension throughout the life of the connection

- 360° uniform sealing pressure

- Resistance to vibration loosening

- Quick assembly in production environments

- No protruding parts that might catch or cause injury

CLIC clamps are particularly ideal for high-volume production environments where speed of assembly is critical, or in applications experiencing temperature fluctuations and vibration.

Worm Drive Hose Clamps: American Style

Perhaps the most recognizable type of hose clamp is the American-style worm drive clamp.

How They Work: These clamps consist of a band (typically stainless steel) with a screw mechanism that, when tightened, draws the band tighter around the hose. The band has threads that engage with the worm gear (screw), allowing for precise tightening.

Key Advantages:

- Wide range of adjustability

- Easily accessible screw head for adjustments

- High clamping force

- Cost-effective solution

- Suitable for most general applications

- Available in various materials for different environments

American-style worm drive clamps are exceptionally versatile and remain the go-to choice for many applications where adjustability and reliable performance are needed.

Worm Drive Clamps: German Style

Another popular hose clamp is the German-style worm drive clamp. They offer several enhancements over their American counterparts.

Curious about how German-style clamps compare to Swedish options? Check out our detailed comparison in Worm Drive Hose Clamps: German vs. Swedish

How They Work: Similar to American-style clamps, these use a worm screw mechanism. However, German-style clamps typically feature a smoother band with rolled edges, a more precise screw mechanism, and often incorporate a spring that helps maintain tension.

Key Advantages:

- Smoother band prevents damage to the hose

- More precise adjustment capability

- Higher quality construction and materials

- Better resistance to vibration loosening

- Improved corrosion resistance

- Often feature safety mechanisms to prevent over-tightening

These clamps are preferred in applications where a higher quality connection is required, particularly in automotive and industrial systems where reliability is paramount.

Mini Clamps

As systems become more compact and space constraints more challenging, mini clamps have emerged as an essential solution for smaller diameter applications.

How They Work: Mini clamps operate on the same principles as their larger counterparts but are specifically designed for small-diameter hoses and tight spaces. They come in various styles, including miniature versions of worm drives and CLIC designs.

Key Advantages:

- Perfect for tight spaces and small diameter hoses

- Lightweight design

- Precision engineering for reliable performance despite small size

- Available in various materials for different environments

- Ideal for laboratory equipment, small appliances, and compact automotive systems

Mini clamps prove that effective sealing solutions don’t need to be bulky, making them indispensable in today’s increasingly miniaturized technologies.

SELECTING THE RIGHT HOSE CLAMP

1. Application Requirements

When selecting a hose clamp, consider these fundamental questions:

- Pressure requirements: What pressure will the system operate under?

- Temperature variations: Will the connection experience significant temperature fluctuations?

- Vibration exposure: Is the connection subject to continuous vibration?

- Space constraints: How much clearance exists around the connection?

- Access for maintenance: Will the clamp need future adjustments?

- Environmental factors: For specialized environments like marine applications, see our guide on Best Hose Clamps for Boats

2. Material Compatibility

The environment your clamp will operate in dictates the appropriate material:

- Stainless steel: Offers excellent corrosion resistance for most applications

- Zinc-plated steel: Provides good corrosion resistance at a lower cost

- Nylon: Non-conductive and suitable for lightweight applications

- Specialty alloys: For extreme chemical or temperature environments

- Color-coded options: For organized systems and quick identification – learn more about Why Use Color-Coded Hose Clamps

3. Size Considerations

Proper sizing is crucial for effective sealing:

- Choose a clamp that matches the outer diameter of the hose

- Allow for compression of the hose material

- Consider the wall thickness of the hose

- Ensure sufficient bandwidth for proper pressure distribution

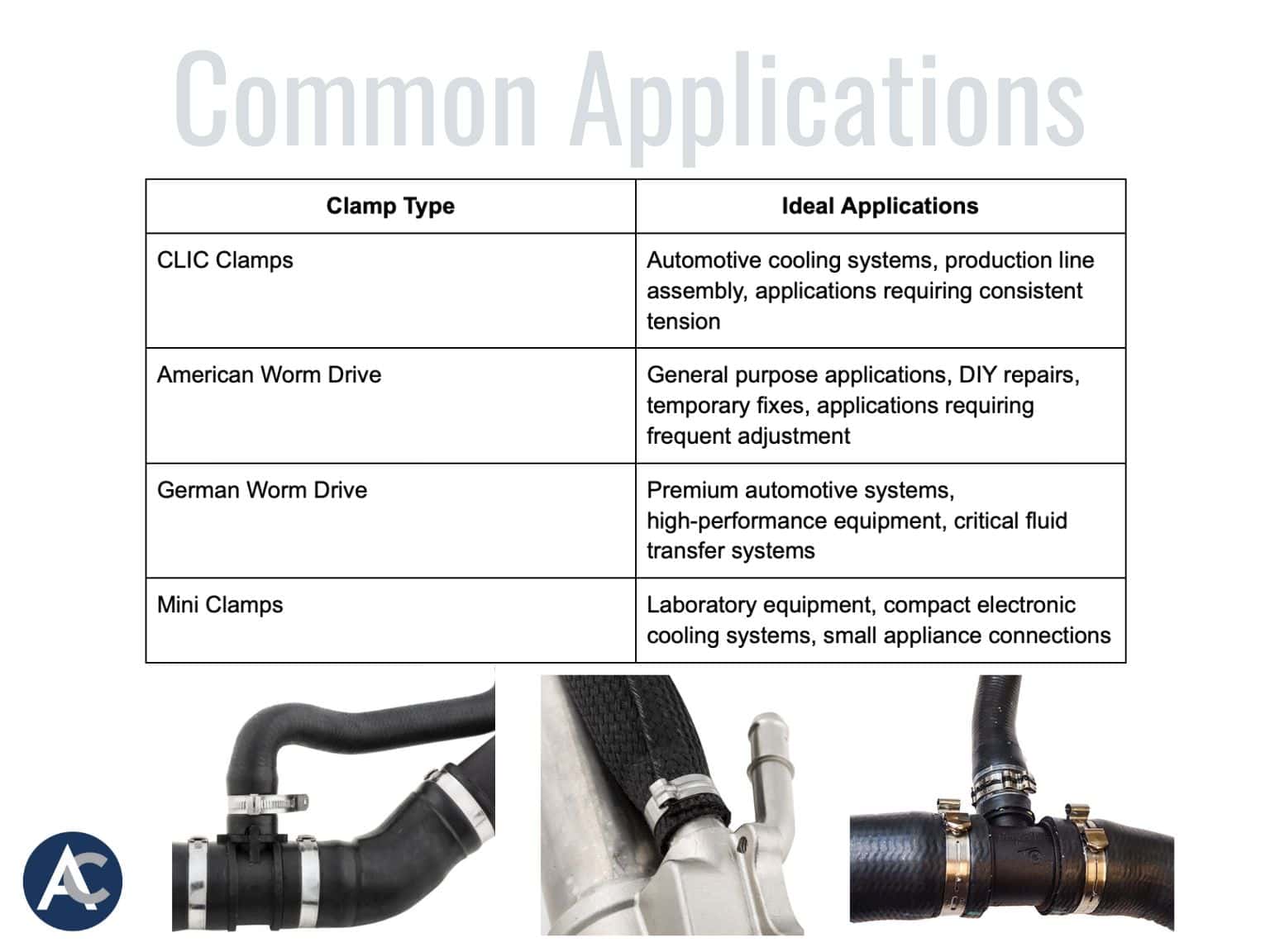

COMMON APPLICATIONS FOR HOSE CLAMPS

Each hose clamp type has applications where it particularly excels:

INSTALLATION BEST PRACTICES

Even the best-designed clamp can fail if improperly installed:

- Proper positioning: Center the clamp over the fitting, not at the edge of the hose

- Appropriate torque: Follow manufacturer specifications to avoid under or over-tightening

- Orientation matters: Position screw mechanisms for easy access during maintenance

- Check for pinching: Ensure the hose isn’t pinched or deformed after tightening

- Multiple clamps: For critical applications, consider using two clamps per connection

WHY SOURCE QUALITY MATTERS

While hose clamps might seem like simple components, the difference between premium and substandard clamps becomes apparent in critical applications. Advance Components specializes in high-performance fastening solutions, including comprehensive offerings of hose clamps that meet exacting standards:

- CLIC Hose Clamps: Engineered for consistent tension and tool-free installation

- Worm Drive Hose Clamps (American Style): Versatile, reliable performers for general applications

- Worm Drive Clamps (German Style): Premium construction for demanding environments

- Mini Clamps: Precision-engineered solutions for compact applications

Each clamp undergoes rigorous quality control to ensure consistent performance in the field, minimizing the risk of leaks, failures, and costly downtime.

THE RIGHT CLAMP MAKES ALL THE DIFFERENCE

While often overlooked, the humble hose clamp represents a critical component in countless fluid transfer systems. Choosing the right type—whether it’s the consistent tension of a CLIC clamp, the versatility of an American-style worm drive, the premium performance of a German-style worm drive, or the compact efficiency of a mini clamp—can significantly impact system reliability and longevity.

For applications where failure isn’t an option, partnering with a trusted supplier like Advance Components ensures access to quality fastening solutions backed by technical expertise and consistent availability. We are a distributor of Caillau and IFE hose clamps. Buy online 24/7, or if you don’t see the part you need, contact us to order.