Rivets are essential permanent fasteners used across numerous industries to create strong, reliable connections between materials. Whether you’re working with metal, plastic, or wood, understanding how rivets function can help you select the right fastening solution for your project. This quick guide explores rivet mechanics, types, installation methods, and applications.

What Is a Rivet?

A rivet is a mechanical fastener consisting of a head and a cylindrical shaft that creates permanent joints between materials. Unlike temporary fasteners such as screws or bolts, rivets form unremovable connections through a deformation of the shaft, making them ideal for applications requiring lasting durability without disassembly.

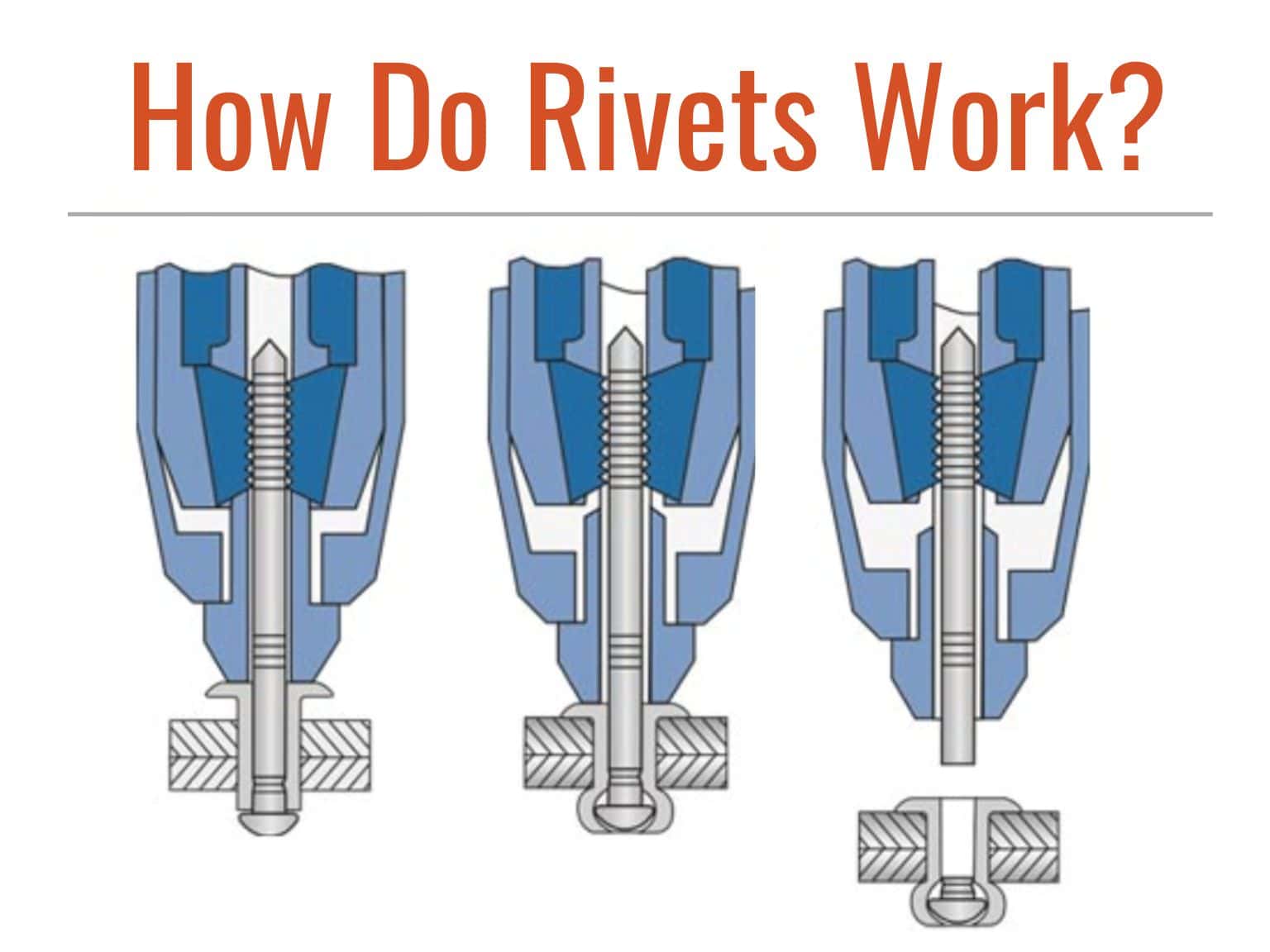

The Rivet Installation Process

The rivet installation process follows these key steps:

- Hole Preparation: Precisely sized holes are drilled through the materials to be joined.

- Rivet Insertion: The rivet is placed into the aligned holes with its head flush against one surface.

- Setting the Rivet: Using specialized tools, force is applied to deform the shaft, creating a second head on the opposite side that locks the materials together.

- Inspection: The completed joint is examined to ensure proper installation and structural integrity.

Types of Rivets for Different Applications

Solid Rivets

Solid rivets, manufactured from a single piece of metal, provide exceptional strength and reliability. These traditional fasteners remain the standard for critical applications in:

- Aerospace structures

- Bridge construction

- Shipbuilding

- Heavy equipment manufacturing

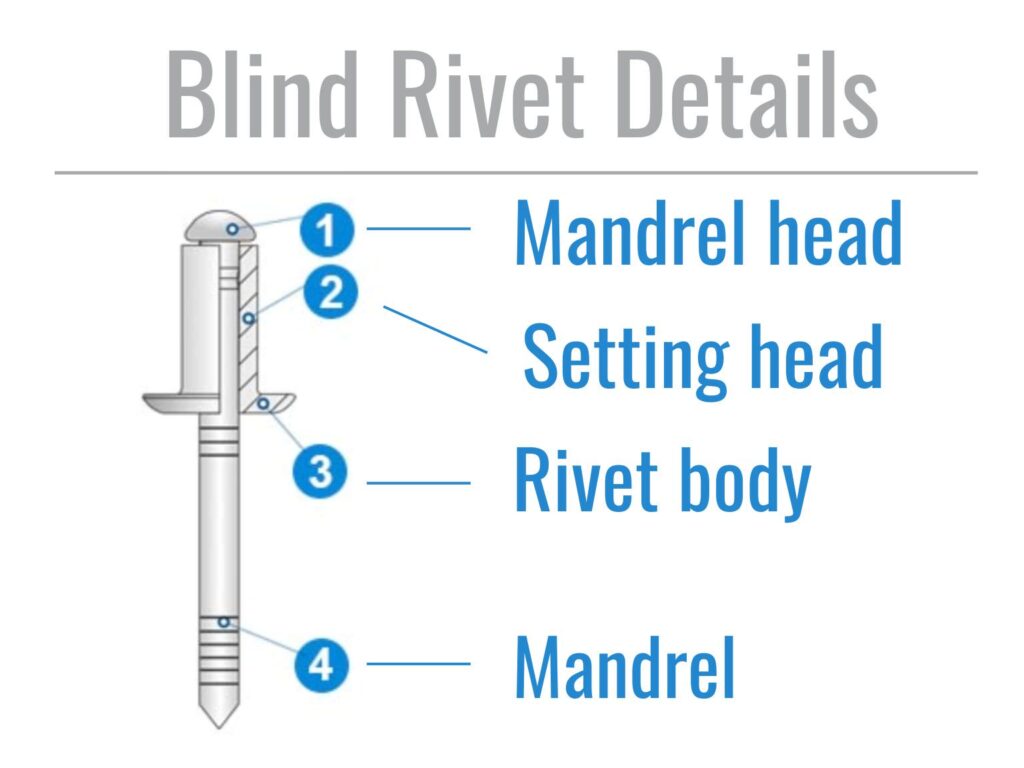

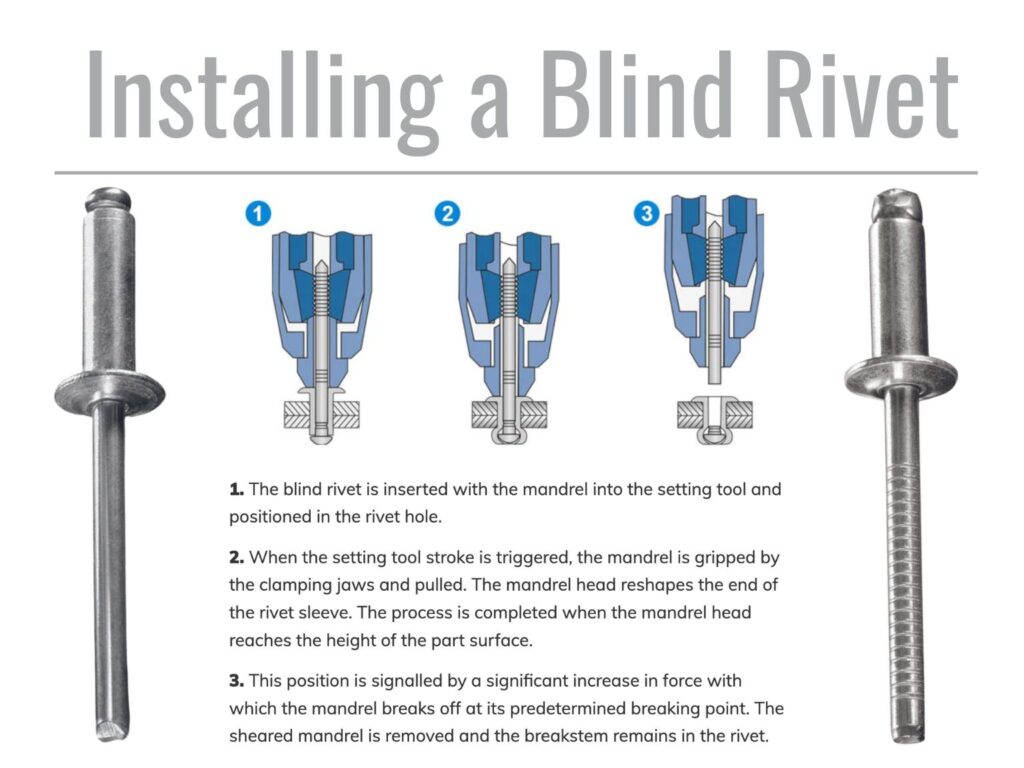

Blind Rivets

Also called “pop rivets,” blind rivets revolutionized fastening by allowing installation from just one side of the workpiece, making them ideal for:

- Automotive body panels

- HVAC ductwork

- Electronics assembly

- Construction applications

Blind Rivet Varieties

- Closed-End Blind Rivets: Offer water-tight sealing and enhanced strength

- Open-End Blind Rivets: Provide economical fastening with excellent load distribution

- Multi-Grip Rivets: Accommodate varying material thicknesses

- Structural Blind Rivets: Deliver high-strength connections for critical applications

Specialty Rivets

- Drive Rivets: Installed using hammer force without specialized tools

- Split Rivets: Feature pre-split tails that spread during installation

- Tubular Rivets: Hollow-centered for electrical connections or lightweight applications

- Semi-Tubular Rivets: Provide controlled deformation with partial hollowness

Professional Rivet Installation Tools

The quality of your tools is critical for successful rivet installation. At Advance Components, we stock a comprehensive range of professional-grade rivet tools designed for efficiency, precision, and durability:

- FAR Rivet Tools: Ergonomically designed tools that reduce operator fatigue while ensuring precision installation, perfect for manufacturing environments requiring repeated rivet placement.

- Gage Bilt Pneumatic, Hydraulic and Cordless Tools: Industrial-strength tools engineered for high-volume production environments, providing consistent, reliable performance for demanding applications.

- GOEBEL Cordless Rivet Tools: Battery-powered precision tools combining portability with professional-grade performance, ideal for field work and installations where air supply isn’t available.

These professional tools handle challenging jobs while maintaining the precision and reliability your projects demand.

Advantages of Riveted Connections

Rivets offer numerous benefits over alternative fastening methods:

- Superior Vibration Resistance: Maintain integrity in high-vibration environments

- Excellent Fatigue Strength: Withstand repeated stress cycles without loosening

- Material Compatibility: Join dissimilar materials without galvanic corrosion concerns

- Speed of Installation: Enable rapid assembly in production environments

- Aesthetic Appeal: Provide clean, professional appearance in visible applications

- Cost-Effectiveness: Reduce overall project expenses through efficient installation

Industrial Applications for Riveted Joints

Rivets serve as crucial components across diverse industries:

- Aviation: Structural aircraft components requiring lightweight yet durable connections

- Automotive Manufacturing: Body panels, frame elements, and interior components

- Construction: Metal roofing, facades, structural joints, and architectural features

- Electronics: Circuit board mounting and component assembly

- Furniture Production: Frame construction and decorative elements

- Metal Fabrication: Sheet metal joining and structural connections

Selecting the Right Fastener for Your Project

When choosing rivets, consider these critical factors:

- Material Compatibility: Match rivet composition to your base materials

- Joint Strength Requirements: Determine load-bearing needs and stress factors

- Environmental Conditions: Consider exposure to moisture, chemicals, or temperature extremes

- Installation Accessibility: Evaluate whether both sides of the joint can be accessed

- Aesthetic Requirements: Decide if the rivet appearance matters for your application

High-Quality Riveting Solutions from Advance Components

When your project demands superior fastening solutions, Advance Components is your trusted source for premium rivets and installation tools. Our extensive selection includes blind and solid rivets, and specialty fasteners designed for diverse applications across industries.

Whether you need FAR, Gage Bilt, or GOEBEL rivet tools, we offer only the highest quality products from leading manufacturers. Explore our catalog and discover why professionals consistently choose Advance Components for their critical fastening requirements.

Elevate your fastening capabilities. Shop our selection of rivets and tools online 24/7 or contact our expert team for personalized recommendations tailored to your specific application needs.