5 Top Styles of Blind Threaded Inserts

Blind threaded inserts are a cost-saving fastening solution for a wide variety of industrial applications. They are ideal for applications in thin metal, plastics and composites.

What are blind threaded inserts? Inserts have either internal or external threads, and can be installed in only one side of a panel or parent material without the need to see the other side – or “blind” side – to complete the installation. Once in place, threaded inserts replace captive and ready to receive a mating component using standard hardware.

AVK Industrial Products is the leading domestic manufacturer of blind threaded inserts. Here we explore 5 styles that are used in “blind” industrial applications.

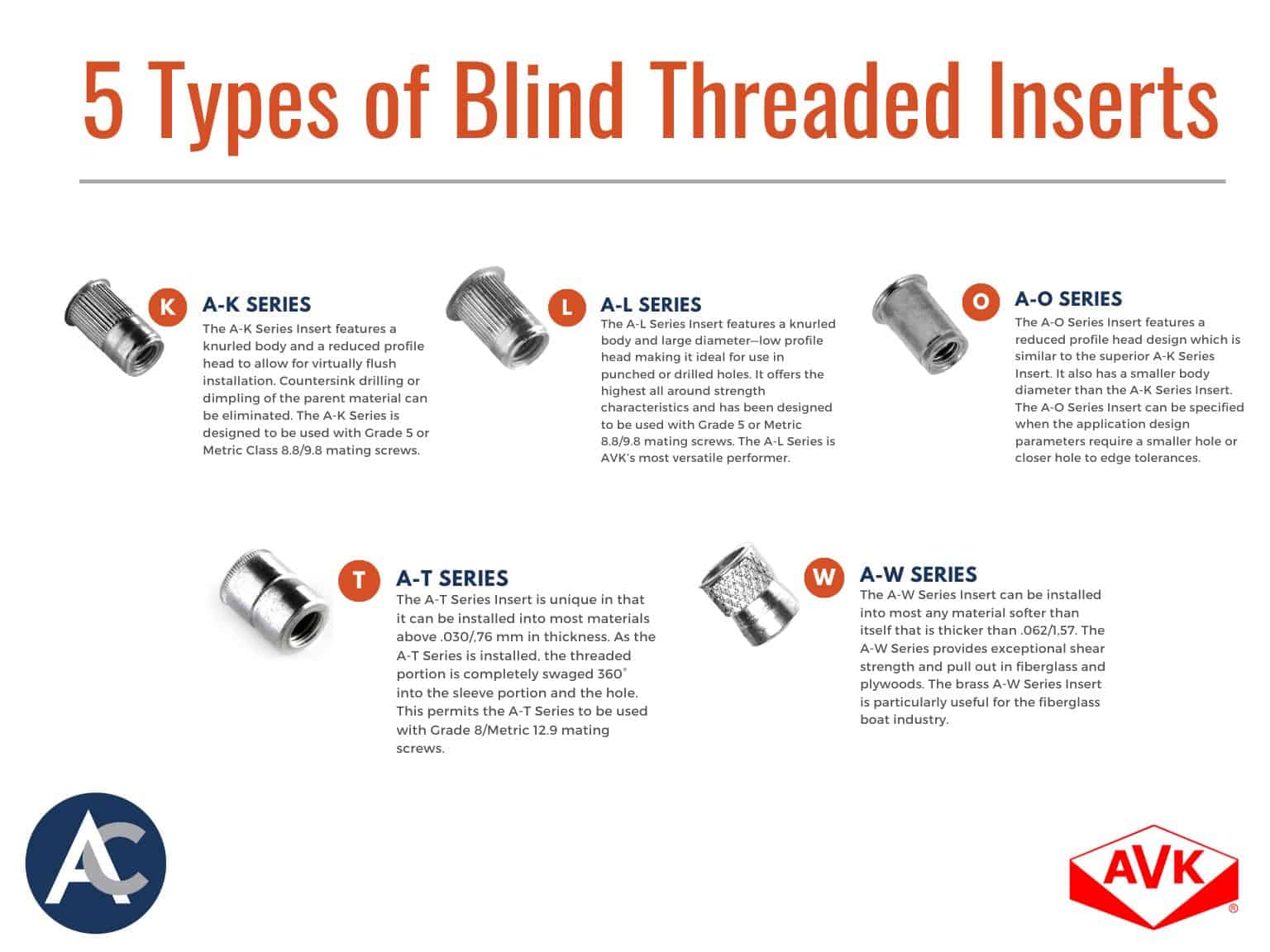

AVK A-K Series Insert

A-K Series Inserts by AVK have exceptionally strong torque-out and pull-out characteristics. A-K blind threaded inserts are very effective in very thin, as well as, thick sheet metal, in both blind and open applications.

The axial knurl on the A-K Series Insert is first forced into the parent material and then upset over the backside to engage the knurl into the parent material which provides a very high resistance to spinning. The “bubble” of material over the backside of the blind threaded insert provides very high pull-out loads.

Benefits and features of A-K Series Inserts

- High torque-out values resists spinning due to cross-threading or overtightening

- High pull-out values

- Blind installation – no access to backside required

- Wide grip range – one length does the job of numerous other inserts

- Nearly flush – no need to counter sink or dimple due to very slight head protrusion

- Installs after surface finish – tool will not mar parent material

- Portable high speed tooling – install at any convenient location on assembly line

- Internal thread lock available

AVK A-L Series Insert

A-L Series Inserts have a large head for applications where large or irregular holes are a problem. A-L Series blind threaded inserts can be installed in sheet metal, structural foam, fiberglass and some plastics.

The axial knurl on the insert is forced into the parent material and then upset over the backside. The knurl engages into the parent material creating a very high resistance to spinning and pull-out loads.

Benefits and features of A-L Series Inserts

- Useable in oversized and irregular holes

- Resists spinning out

- Pull-out proof due to “bubble” on the backside

- Can install on one-side of panel

- Wide range of grip

- Near flush installation

- Can install after surface finishing

- Easy to install in any area of assembly line

- Sealed head available

AVK A-T Series Insert

A-T Series Inserts by AVK are the “non-grip sensitive” inserts that will work in “any” thickness over .030. The installation tool pulls the “cone” shaped nut into a sleeve expanding into the parent material.

When installed, the A-K blind threaded insert is completely swagged 360 degrees into the sleeve portion and the hole. It can be used with Grade 8/Metric 12.9 mating screws.

Benefits and features of A-T Series Inserts

- One length works in any thickness over .030

- Blind installs from one side of the work piece

- Installation will not mar parent material

- High-resistance to torque out

- Portable tools for installation anywhere

- Nearly flush installation – approximately .015 protrusion

- Ideal for high speed installation – up to 5000 pieces per hour

- Vibration resistant

- Can be installed after finish work

- No hole de-burring required

- Uses standard drilled holes

AVK A-W Series Insert

A-W Series Inserts by AVK are ideal for use in soft materials such as plastics, fiberglass, wood, structural foam, aluminum, etc. The installation tool pulls a “cone” shaped nut into a sleeve expanding the unique “diamond knurl” into the parent material.

The “diamond knurl” feature on the A-W blind threaded insert produces very high torque-out resistance and pull-out values. A-W inserts are ideal for use in thinner materials where the shallowest insert protrusion on the backside is desired.

Benefits and features of A-W Series Inserts

- Can install after painting

- Use in standard drilled holes

- Blind installation

- Ideal for high speed installation

- Wear resistant threads

- Near flush installation at .015

- Installation will not mar parent material

A-O Series Insert by AVK

A-O Series blind threaded inserts provide very high pull-out loads in thin metal applications. A-O inserts have a reduced profile head design similar to the A-K Series insert, and a smaller body that is ideal for smaller holes.

A-O Series Inserts have a near flush profile when installed, and are ideal for high-torque tolerances on hole to edge applications.

Benefits and features of A-O Series Inserts

- Blind installation

- Nearly flush installation

- Portable tooling for application anywhere on assembly line

- Wide grip range

- Can be installed after painting or plating

So as you can see, blind threaded inserts vary in application features and size, but they all provide a secure fastening solution for a variety of thin materials. Using inserts instead of welding reduces the carbon footprint and costs due to equipment needed for air scrubbing, vacuuming and repainting after application.

AVK Industrial Products have been stocked and distributed by Advance for over 35 years. Our sales team is highly trained in applications, and is always eager to help our customers find the right part for the job. Keep your knowledge of AVK Blind Threaded Inserts handy with this downloadable PDF.