What is a Nut Retainer?

Nut Retainers are self-retaining spring steel fasteners that have a bolt-receiving nut floating inside a cage that off-sets normal hole misalignment and doesn’t turn when the bolt is tightened.

Nut Retainers can either slide or snap into position at panel edges or center-panel locations, and are ideal for blind assembly locations.

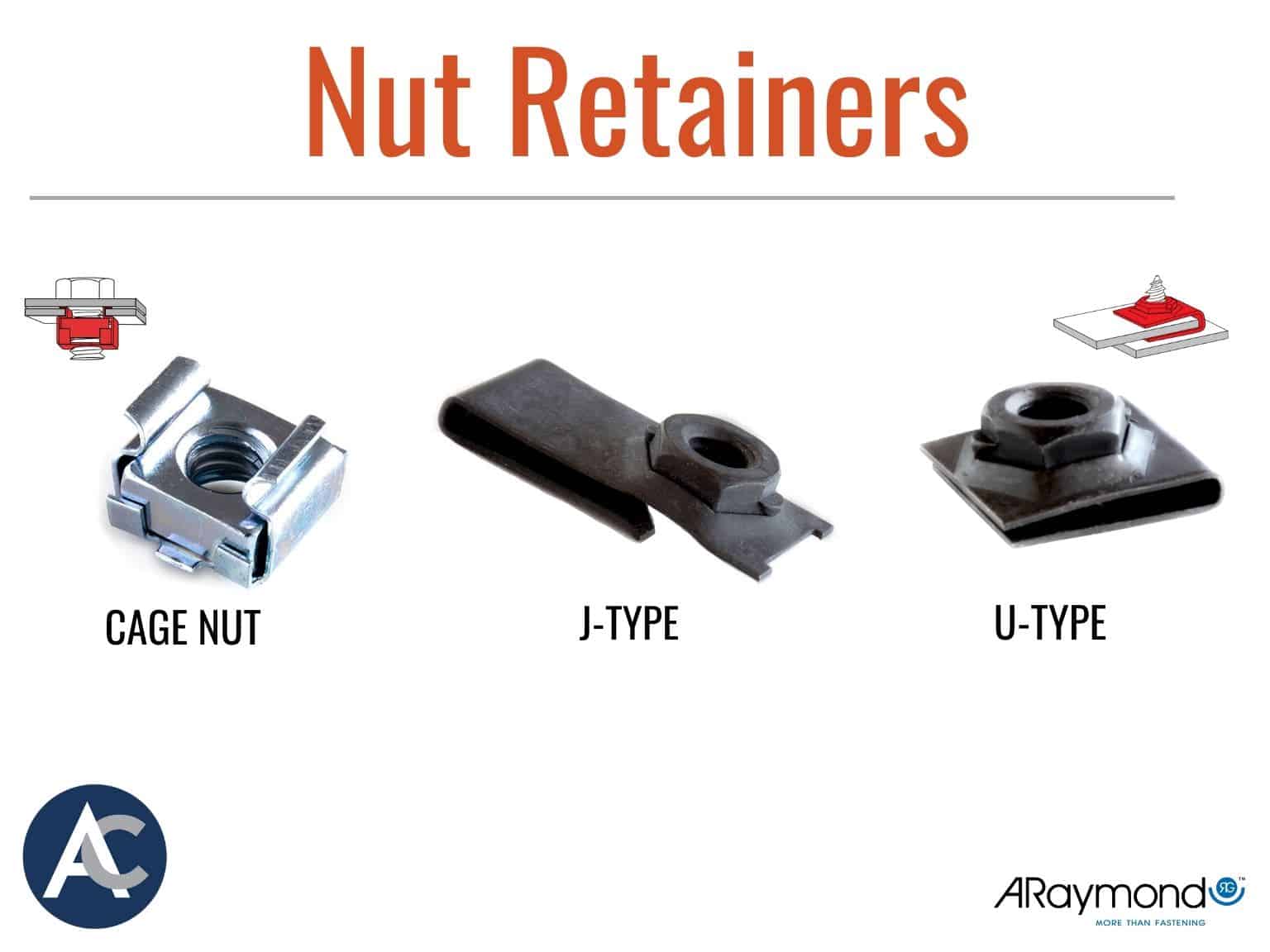

The top 3 types of nut retaining fasteners are Cage Nuts or Rack Nuts, J-type and U-type Nut Retainers. Each type is ideal for applications requiring extra-high torque and holding power. Self-retaining Nut Retainers can easily be snapped into nut- or bolt-receiving position by hand, anywhere along the assembly line.

No welding, clinching, staking, special skills or equipment are required for application. Nut Retainers are rust-proof, and can be applied after painting, eliminating costly masking or retaping of paint-clogged threads.

3 Types of Nut Retaining Fasteners

Cage Nuts, Rack Nuts, Captive Nuts

Cage Nuts, Rack Nuts or Captive Nuts are a combination of a strong spring steel cage and a multi-threaded nut. The nut floats within a spring steel cage more than enough to offset normal hole misalignment. It has “mechanical legs” which hold the nut in screw-receiving position for blind assembly attachments.

How to Apply Cage Nuts

-

- One retaining leg of the Cage Nut is inserted in the panel hole.

- The other leg is snapped into the hole with a simple tool or by hand.

- The second panel is aligned and the bolt is threaded onto the captive nut.

- The bolt is tightened into the self-retaining nut.

- A positive, high-torque, flush attachment is achieved.

J-Type

J-Type or J-Nut Retainers snap over panel edges or are inserted into rectangular holes in central panel locations. Floating alignment and retention are attained with extrusions in the retaining legs which snap into panel mounting holes, allowing the fastener to shift or align, but not disengage.

J-Type or J-Nut Retainers snap over panel edges or are inserted into rectangular holes in central panel locations. Floating alignment and retention are attained with extrusions in the retaining legs which snap into panel mounting holes, allowing the fastener to shift or align, but not disengage.

How to Apply J-Type Nuts

-

- Push into place on the panel, or into a rectangular hole in the panel center

- Snap the extrusion into hole.

- Position second panel and drive screw

- Both hands are free to align panels

- Flush mounting is obtained with embossing either panel

U-Type

U-Type or U-Nut Retainers offer the same advantages as J-Type Nut Retainers – heavy duty fastening, low fasteners profile, “float” for hole misalignment, self-retention, and blind location assembly. U-Type Nut Retainers have a full-sized lower leg that is preferred for a full bearing surface between panels.

How To Apply U-Type Nuts

-

- Push into bolt-receiving position on the panel, or place in a rectangular hole in the center.

- Snap the extrusion into the mounting hole.

- Position the second panel and drive the screw.

- Flush mounting is obtained

- Access to back of panel is unnecessary to complete assembly.

Applications for Nut Retainers

- Appliances

- Electronics

- Computer Server Racks

- Signage

- Vending

- Automotive

- Marine

- HVAC

- Military

- Utility Vehicles

ARaymond/Tinnerman manufacturers a large variety of nut retaining fasteners. As an authorized master distributor of ARaymond/Tinnerman products, Advance Components stocks and distributes all styles of Nut Retainers. Our sales team is highly trained in applications, and is always happy to help our customers find the right part for the job.