Socket head cap screws, also known as Allen head screws, hex socket screws, or socket cap screws, are specialized fasteners featuring cylindrical heads with recessed hexagonal drive holes. These high-strength fasteners are essential components in aerospace, industrial machinery, and precision assembly applications where space constraints and superior holding power are critical.

Socket Head Cap Screw Basics

What Makes Socket Head Cap Screws Different?

Socket head cap screws are distinguished by their cylindrical heads with flat chamfered tops and internal hexagonal drives. Standard socket head cap screws feature head heights equal to their thread diameter, while low-profile variants offer reduced head height for applications with limited clearance.

Key Characteristics:

-

Installation Tool: Hex Allen keys or socket wrenches

-

Head Design: Cylindrical with recessed hex drive

-

Threading Options: Fully threaded or partially threaded configurations

-

Strength Grade: Higher tensile strength than conventional cap screws

-

Appearance: Smooth, flush finish when properly installed

Socket Head Cap Screw vs. Standard Cap Screws

Unlike traditional hex head cap screws, socket head cap screws provide:

-

Space Efficiency: Compact head design for tight spaces

-

Higher Strength: Superior tensile and yield strength ratings

-

Clean Appearance: Flush mounting capability

-

Precision Assembly: Ideal for machinery and precision equipment

Key Applications and Industries

Aerospace Applications

Aerospace screws and socket head cap screws are critical in:

-

Aircraft panel assembly and maintenance

-

Avionics mounting and enclosures

-

High-temperature engine components

-

Weight-sensitive structural applications

Industrial Machinery

-

CNC machine tool assemblies

-

Hydraulic and pneumatic systems

-

Conveyor and automation equipment

-

Precision jig and fixture applications

Commercial Applications

-

Electronic enclosure assembly

-

Furniture and architectural hardware

-

Automotive aftermarket modifications

-

Marine and recreational vehicle assembly

7 Essential Socket Head Cap Screw Styles

1. 18-8 Stainless Steel Socket Head Cap Screws

Material Properties:

-

Grade: 18-8 Stainless Steel (304 equivalent)

-

Corrosion Resistance: Excellent chemical resistance

-

Vibration Resistance: Superior to standard carbon steel

-

Temperature Range: -400°F to 800°F operating range

Available Configurations:

-

Standard and metric threading (M3 to M20, #4 to 1″)

-

Fully threaded and partially threaded options

-

Length measurement from under head

2. 18-8 Stainless Steel Low Profile Socket Head Cap Screws

Design Features:

-

Head Height: 50% reduction compared to standard socket screws

-

Internal Drive: Smaller hex socket size

-

Clearance Requirements: Minimal vertical space needed

-

Torque Limitations: Lower preload capacity than standard heads

Engineering Considerations:

-

Not recommended for high-torque applications

-

Ideal for flush-mount installations

-

Perfect for panel and cover plate assembly

-

Reduced clamping force compared to standard height screws

3. Black Oxide Alloy Steel Socket Head Cap Screws

Material Specifications:

-

Base Material: Alloy steel construction

-

Finish: Matte black oxide coating

-

Corrosion Protection: Enhanced rust resistance

-

Strength Grade: Higher tensile strength than stainless options

Performance Benefits:

-

Chemical resistance superior to plain steel

-

Vibration-proof design for dynamic applications

-

Available in both metric and imperial sizing

-

Cost-effective alternative to stainless steel

Threading Options:

-

Fully threaded: Complete thread engagement

-

Partially threaded: Unthreaded shank for enhanced shear strength

4. Black Oxide Low Profile Socket Head Cap Screws

Combining the space-saving benefits of low-profile design with the strength of black oxide alloy steel, these socket head cap screws are ideal for:

-

Tight clearance machinery applications

-

Automotive panel fastening

-

Electronics enclosure assembly

-

Industrial equipment covers and guards

5. Black Oxide SEMS Socket Head Cap Screws with Flat Washer

SEMS Assembly Features:

-

Pre-assembled Washer: Permanently attached flat washer

-

Load Distribution: Wider bearing surface area

-

Installation Efficiency: Single-component assembly

-

Surface Protection: Prevents substrate damage during fastening

Technical Advantages:

-

Freely rotating washer design

-

Consistent clamping pressure distribution

-

Reduced assembly time and labor costs

-

Ideal for soft materials and thin-wall applications

6. A286 High-Strength Stainless Steel Socket Head Cap Screws

Superior Material Properties:

-

Alloy Composition: A286 super-austenitic stainless steel

-

Strength Characteristics: Combines alloy steel strength with stainless corrosion resistance

-

Temperature Rating: Maintains properties at elevated temperatures

-

Applications: Critical aerospace and high-performance industrial uses

Performance Specifications:

-

Tensile Strength: 140,000 PSI minimum

-

Yield Strength: 95,000 PSI minimum

-

Hardness: Rockwell C 35-42

-

Threading: Available in fully and partially threaded configurations

Industries Served:

-

Aerospace fastener applications

-

High-temperature industrial processes

-

Chemical processing equipment

-

Power generation systems

7. B7 Alloy Steel Socket Head Cap Screws

Grade B7 Specifications:

-

Material Standard: ASTM A193 Grade B7 alloy steel

-

Temperature Rating: Continuous service to 1100°F

-

Tempering Process: Specially heat-treated for high-temperature performance

-

Threading: Fully threaded configuration standard

High-Temperature Applications:

-

Pressure vessel assembly

-

Steam and thermal systems

-

Industrial furnace components

-

Power plant maintenance and construction

Mechanical Properties:

-

Tensile Strength: 125,000 PSI minimum

-

Yield Strength: 105,000 PSI minimum

-

Elongation: 16% minimum in 2 inches

-

Reduction of Area: 50% minimum

Material Specifications and Grades

Understanding Socket Head Cap Screw Materials

Different applications require specific material properties. Here’s a comprehensive breakdown:

Stainless Steel Grades:

-

18-8 (304): General purpose, excellent corrosion resistance

-

A286: High-strength, high-temperature applications

-

316: Superior corrosion resistance in marine environments

Alloy Steel Options:

-

Grade B7: High-temperature service applications

-

Black Oxide Coated: Enhanced corrosion protection

-

Plain Steel: Cost-effective for standard applications

Installation and Technical Requirements

Proper Torque Specifications

Socket head cap screws require specific torque values based on:

-

Material Grade: Stainless vs. alloy steel

-

Thread Size: M3 through M20, #4 through 1″

-

Application Type: Static vs. dynamic loading

-

Environmental Conditions: Temperature and chemical exposure

Allen Key and Hex Socket Selection

Standard Hex Key Sizes:

-

Metric: 1.5mm to 17mm

-

Imperial: 1/16″ to 3/4″

-

Quality Requirements: Use hardened steel hex keys for optimal performance

-

Torque Transfer: Properly sized tools prevent socket damage

Threading Considerations

Fully Threaded Applications:

-

Maximum thread engagement

-

Ideal for through-hole applications

-

Better for adjustable assemblies

Partially Threaded Benefits:

-

Enhanced shear strength

-

Reduced thread wear in blind holes

-

Superior clamping force concentration

Socket Head Cap Screw Selection Guide

Choosing the Right Socket Head Cap Screw

Consider These Factors:

-

Environmental Conditions: Corrosion, temperature, chemicals

-

Mechanical Requirements: Tensile strength, fatigue resistance

-

Space Constraints: Head height, access limitations

-

Assembly Requirements: Torque specifications, installation tools

-

Regulatory Compliance: DFARS, military specifications, industry standards

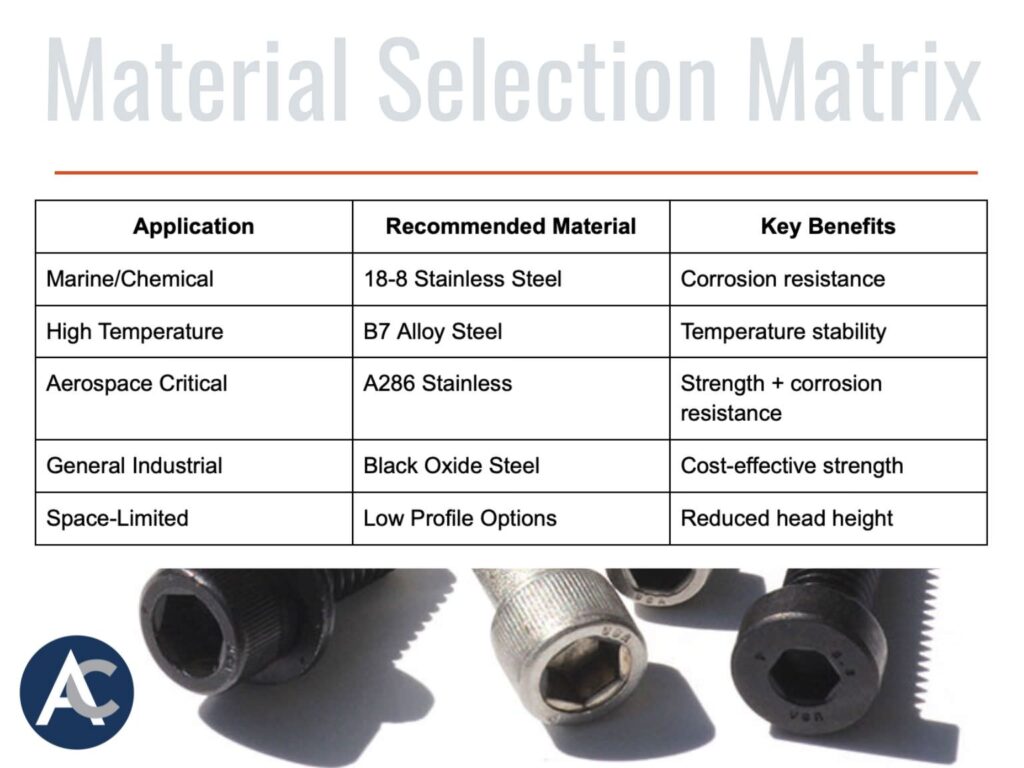

Material Selection Matrix

Why Choose DFARS-Compliant Socket Screws

Parker Fasteners Manufacturing Excellence

Parker Fasteners leads U.S. socket head cap screw manufacturing with:

-

Cold Heading Process: Superior strength and consistency

-

DFARS-Compliant Steel: Domestic sourcing requirements met

-

Quality Certifications: ISO 9001 and military specification compliance

-

Custom Solutions: Specialized sizes and configurations available

DFARS Compliance and Material Sourcing

DFARS-sourced materials are essential for government and military applications. All Parker Fasteners socket head cap screws use compliant materials, ensuring:

-

Domestic steel sourcing requirements

-

Quality traceability and documentation

-

Military specification compliance

-

Enhanced security for sensitive applications

Advance Components Partnership Advantages

As an authorized Parker Fasteners master distributor, Advance Components provides:

Inventory Advantages:

-

Large variety of socket screws in stock

-

Same-day shipping capabilities

-

Custom kitting and packaging services

-

Technical application support

Value-Added Services:

-

Engineering consultation and application support

-

Supply chain solutions integration

-

Quality documentation and certifications

-

Inventory management programs

Forging the Future with Quality Socket Head Cap Screws

Socket head cap screws represent the intersection of precision engineering and practical application. Whether you’re assembling aerospace components, industrial machinery, or specialized equipment, choosing the right socket head cap screw style and material is crucial for long-term performance and reliability.

Parker Fasteners socket head cap screws, available through Advance Components, provide the strength, precision, and quality needed for demanding applications. From standard 18-8 stainless steel to specialized A286 and B7 high-temperature alloys, our comprehensive selection ensures you’ll find the perfect fastener solution.

Ready to specify socket head cap screws for your next project?

Contact our technical team for application-specific recommendations, or browse our complete socket head cap screw inventory to find exactly what you need. With same-day shipping and comprehensive technical support, Advance Components is your trusted partner for precision fastener solutions.

For additional technical specifications, material certifications, or custom socket head cap screw requirements, contact Advance Components at sales@advancecomponents.com. Our experienced technical team provides application engineering support to ensure optimal fastener performance in your specific application.